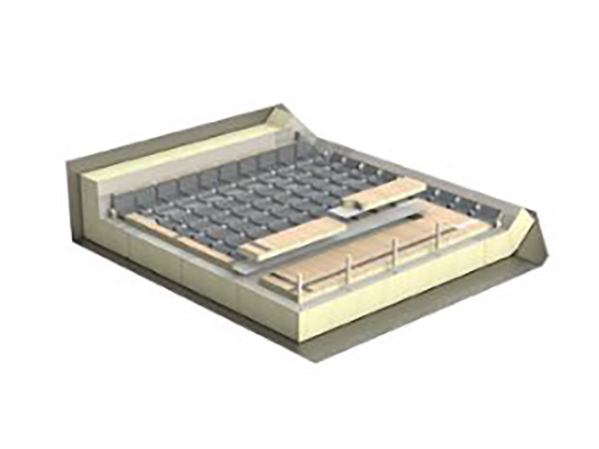

Versatile Continuous Filament Mat for PU Foam Manufacturing

FEATURES & BENEFITS

● Greatly reduced binder

● The mat layers are prone to delamination

● Low filament count per bundle

PRODUCT CHARACTERISTICS

| Product Code | Weight(g) | Max Width(cm) | Solubility in styrene | Bundle density(tex) | Solid content | Resin compatibility | Process |

| CFM981-450 | 450 | 260 | low | 20 | 1.1±0.5 | PU | PU foaming |

| CFM983-450 | 450 | 260 | low | 20 | 2.5±0.5 | PU | PU foaming |

● Other weights available upon request.

● Other widths available upon request.

● CFM981 exhibits exceptionally low binder content. This property allows it to distribute uniformly in the PU matrix as the foam expands, resulting in superior reinforcement for the structural integrity and thermal reliability of LNG carrier insulation panels.

PACKAGING

● Inner Core Options:

- Available Diameters: 3" (76.2 mm) or 4" (102 mm)

- Wall Thickness: Minimum 3 mm (standard across all sizes)

- Key Benefit: Ensures superior strength and operational stability.

● Protective Packaging:

- Method: Individual wrapping with protective film for each roll and pallet.

- Shields Against: Dust, moisture, and external impact.

- Purpose: To guarantee integrity during transportation and storage.

● To ensure complete traceability, each roll and pallet is labeled with a unique barcode. Key data points like weight, roll quantity, and production date are encoded, enabling streamlined logistics and precise inventory management.

STORAGING

● Optimal Storage Conditions:

- Environment: A cool, dry warehouse.

- Purpose: To ensure long-term stability and maintain specified performance characteristics.

● For optimal preservation, the storage temperature must be kept within the range of 15°C to 35°C.

● For optimal performance, the storage environment is defined as 35% to 75% relative humidity. Levels outside this range may adversely affect material handling and application.

● To ensure structural integrity, pallet stacking must not exceed two layers, thus preventing deformation and compression damage.

● To achieve optimal processing performance, the mat requires a minimum acclimatization period of 24 hours in the worksite environment before application.

● Handling Partially Used Packages:

- Requirement: Properly reseal after each use.

- Object: The original packaging.

- Purpose: To ensure quality and prevent contamination or moisture absorption of the remaining material.