Versatile Combo Mats for Every Project Requirement

Stitched mat

Description

This mat is formed from precisely chopped strands that are uniformly spread and stitched together with polyester yarn. The strands feature a silane coupling agent sizing, ensuring excellent compatibility with unsaturated polyester, vinyl ester, epoxy, and other resin systems. This structure, with its even strand distribution, provides stable and reinforced mechanical performance.

Features

1. Guarantees uniform weight and thickness, superior mat integrity, and a clean, residue-free performance with no loose fibers.

2. Reduces processing time

3. Bonds effectively with various resin types.

4. Easy to mold and highly adaptable to intricate contours.

5. Allows for effortless cutting on-site

6.Superior molded appearance

7. High strength and rigidity

|

Product code |

Width(mm) |

Unit weight(g/㎡) |

Moisture Content(%) |

|

SM300/380/450 |

100-1270 |

300/380/450 |

≤0.2 |

Combo mat

Description

Engineered by combining two or more fiberglass materials via stitching, needling, or binders, these composite mats offer outstanding versatility, moldability, and a wide application scope.

Features & benefits

1. By selecting different materials and combinations, these mats are compatible with processes such as pultrusion, RTM, and vacuum injection. They also seat well into intricate molds due to their good conformability.

2. Can be tailored to your specific needs for both structural performance and visual finish.

3. Streamlines the molding process by reducing pre-form cutting and fitting, thereby increasing productivity.

4. Minimizes waste and maximizes workforce efficiency.

|

Products |

Description |

|

|

WR +CSM (Stitched or needled) |

Complexes are typically a combination of Woven Roving (WR) and chopped strands assembled by stitching or needling. |

|

|

CFM Complex |

CFM + Veil |

a complex product composed by a layer of Continuous Filaments and a layer of veil, stitched or bonded together |

|

CFM + knitted Fabric |

This complex is obtained by sewing a central layer of continuous filament mat with knitted fabrics on one or both sides CFM as the flow media |

|

|

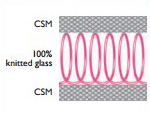

Sandwich Mat |

|

Designed for RTM closed mold applications. 100% glass 3-Dimensional complex combination of a knitted glass fiber core that is stitch bonded between two layers of binder free chopped glass. |