Versatile Combo Mats for Efficient Workspaces

Stitched mat

Description

Stitched mat is produced by evenly distributing chopped strands of a specified length into a fleece, which is subsequently bonded by stitching with polyester yarn. The glass fibers are coated with a silane-based coupling agent sizing, making them compatible with resin systems such as unsaturated polyester, vinyl ester, and epoxy. This uniform fiber distribution results in consistent and reliable mechanical properties.

Features

1. Consistent weight (GSM) and thickness, with secure structural integrity and no fiber shedding.

2.Fast wet-out

3. Excellent chemical affinity:

4. Excellent drapeability for seamless molding around complex shapes.

5.Easy to split

6.Surface aesthetics

7.Excellent mechanical characteristics

|

Product code |

Width(mm) |

Unit weight(g/㎡) |

Moisture Content(%) |

|

SM300/380/450 |

100-1270 |

300/380/450 |

≤0.2 |

Combo mat

Description

Fiberglass combination mats integrate two or more types of fiberglass materials through knitting, needling, or chemical binding, offering exceptional design flexibility, versatile performance, and broad applicability.

Features & benefits

1. Fiberglass composite mats can be customized through the selection of various fiberglass materials and combining techniques—such as weaving, needling, or chemical bonding—to meet the requirements of diverse manufacturing processes including pultrusion, RTM, and vacuum infusion. They offer excellent conformability, enabling them to fit intricate mold geometries with ease.

2. Engineered to fulfill specific mechanical and aesthetic specifications.

3. Minimizes pre-mold preparation and boosts production efficiency

4. Optimizes material and labor resources.

|

Products |

Description |

|

|

WR +CSM (Stitched or needled) |

Complexes are typically a combination of Woven Roving (WR) and chopped strands assembled by stitching or needling. |

|

|

CFM Complex |

CFM + Veil |

a complex product composed by a layer of Continuous Filaments and a layer of veil, stitched or bonded together |

|

CFM + knitted Fabric |

This complex is obtained by sewing a central layer of continuous filament mat with knitted fabrics on one or both sides CFM as the flow media |

|

|

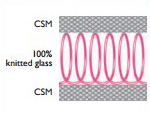

Sandwich Mat |

|

Designed for RTM closed mold applications. 100% glass 3-Dimensional complex combination of a knitted glass fiber core that is stitch bonded between two layers of binder free chopped glass. |