Stitched Mats for Reliable Performance in Tough Environments

Stitched mat

Description

Stitched mat is produced by evenly distributing chopped strands of a specific length into a sheet, which is then bonded with polyester yarn. The fiberglass strands are treated with a silane-based coupling agent. This sizing makes them compatible with various resin systems, such as unsaturated polyester, vinyl ester, and epoxy. The uniform distribution of the strands ensures consistent and excellent mechanical properties.

Features

1. Consistent basis weight and thickness, excellent structural integrity, and free from loose fibers.

2. Rapid impregnation

3. Excellent compatibility with a wide range of resin systems.

4. Excellent drapability over complex mold shapes.

5. Can be easily cut-to-size

6. High-quality surface finish

7. Excellent mechanical performance

|

Product code |

Width(mm) |

Unit weight(g/㎡) |

Moisture Content(%) |

|

SM300/380/450 |

100-1270 |

300/380/450 |

≤0.2 |

Combo mat

Description

Fiberglass combo mats feature a hybrid structure, integrating two or more types of fiberglass materials through stitching, needling, or chemical binders. This construction provides exceptional design flexibility, overall adaptability, and a broad range of applications.

Features & benefits

1. Fiberglass composite mats can be tailored through specific material selections and manufacturing processes to suit various techniques like pultrusion, RTM, and vacuum infusion, while also offering excellent drapability for complex molds.

2. Can be engineered to achieve precise strength and aesthetic targets.

3. Minimizes pre-mold preparation, streamlining production and boosting overall output.

4. Optimizes material and labor utilization.

|

Products |

Description |

|

|

WR +CSM (Stitched or needled) |

Complexes are typically a combination of Woven Roving (WR) and chopped strands assembled by stitching or needling. |

|

|

CFM Complex |

CFM + Veil |

a complex product composed by a layer of Continuous Filaments and a layer of veil, stitched or bonded together |

|

CFM + knitted Fabric |

This complex is obtained by sewing a central layer of continuous filament mat with knitted fabrics on one or both sides CFM as the flow media |

|

|

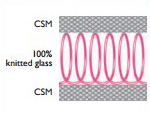

Sandwich Mat |

|

Designed for RTM closed mold applications. 100% glass 3-Dimensional complex combination of a knitted glass fiber core that is stitch bonded between two layers of binder free chopped glass. |