Stitched Fiberglass Mats for Maximum Strength and Flexibility

Stitched mat

Description

Stitched mat consists of chopped fiberglass strands uniformly formed into a fleece and stitched with polyester yarn. It is characterized by a silane-based sizing for resin compatibility (polyester, vinyl ester, epoxy) and an even fiber distribution that ensures stable mechanical performance.

Features

1. Uniform GSM and thickness, good integrity, without loose fiber

2.Fast wet-out

3. Good compatibility

4.Easily conforms to mold contours

5.Easy to split

6.Surface aesthetics

7.Good mechanical properties

|

Product code |

Width(mm) |

Unit weight(g/㎡) |

Moisture Content(%) |

|

SM300/380/450 |

100-1270 |

300/380/450 |

≤0.2 |

Combo mat

Description

Fiberglass combo mats are produced by merging two or more fiberglass material types via knitting, needling, or binder bonding; featuring exceptional designability, structural flexibility, and wide-ranging adaptability for various uses.

Features & benefits

1. The versatility in material and process selection allows fiberglass complex mats to be engineered for specific applications, including pultrusion, RTM, and vacuum injection. This versatility, coupled with their good conformability, makes them suitable for use with complex molds.

2. Offers customization in both structural strength and visual appearance.

3. It decreases the need for pre-mold dressing and tailoring, thereby contributing to significant gains in productivity.

4. Drives down costs associated with both materials and labor.

|

Products |

Description |

|

|

WR +CSM (Stitched or needled) |

Complexes are typically a combination of Woven Roving (WR) and chopped strands assembled by stitching or needling. |

|

|

CFM Complex |

CFM + Veil |

a complex product composed by a layer of Continuous Filaments and a layer of veil, stitched or bonded together |

|

CFM + knitted Fabric |

This complex is obtained by sewing a central layer of continuous filament mat with knitted fabrics on one or both sides CFM as the flow media |

|

|

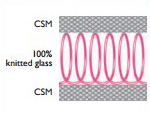

Sandwich Mat |

|

Designed for RTM closed mold applications. 100% glass 3-Dimensional complex combination of a knitted glass fiber core that is stitch bonded between two layers of binder free chopped glass. |