Stitched Fiberglass Mats for Enhanced Load-Bearing Capacity

Stitched mat

Description

Composed of uniformly distributed, chopped strands bonded by polyester stitching, this mat utilizes a silane-based sizing for broad resin compatibility (e.g., polyester, vinyl ester, epoxy), resulting in reliable and consistent mechanical properties.

Features

1. Features uniform GSM and thickness, combined with a secure mat structure that effectively locks in fibers to prevent shedding.

2. Quickly saturated by resin

3. Works well with multiple resins.

4. Faithfully replicates the precise details of the mold surface.

5. Readily separable for custom applications

6. Excellent visual appeal

7. Delivers superior structural integrity

|

Product code |

Width(mm) |

Unit weight(g/㎡) |

Moisture Content(%) |

|

SM300/380/450 |

100-1270 |

300/380/450 |

≤0.2 |

Combo mat

Description

Defined as a non-woven material that combines different fiberglass types through mechanical or chemical bonding, fiberglass combo mats are characterized by their superior versatility and design flexibility.

Features & benefits

1. The mats can be engineered with different materials and structures to match specific processes (pultrusion, RTM, vacuum infusion). This adaptability, combined with their inherent conformability, allows them to fit complex mold geometries effectively.

2. Capable of delivering the specific mechanical properties and surface quality required.

3. Saves time and cost by reducing in-mold trimming and adjustments, leading to higher throughput.

4. Delivers enhanced operational efficiency through reduced material usage and labor requirements.

|

Products |

Description |

|

|

WR +CSM (Stitched or needled) |

Complexes are typically a combination of Woven Roving (WR) and chopped strands assembled by stitching or needling. |

|

|

CFM Complex |

CFM + Veil |

a complex product composed by a layer of Continuous Filaments and a layer of veil, stitched or bonded together |

|

CFM + knitted Fabric |

This complex is obtained by sewing a central layer of continuous filament mat with knitted fabrics on one or both sides CFM as the flow media |

|

|

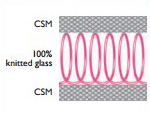

Sandwich Mat |

|

Designed for RTM closed mold applications. 100% glass 3-Dimensional complex combination of a knitted glass fiber core that is stitch bonded between two layers of binder free chopped glass. |