Roving-xidhashada: Ku Wanaagsan Isku-dhafka Waxqabadka Sare

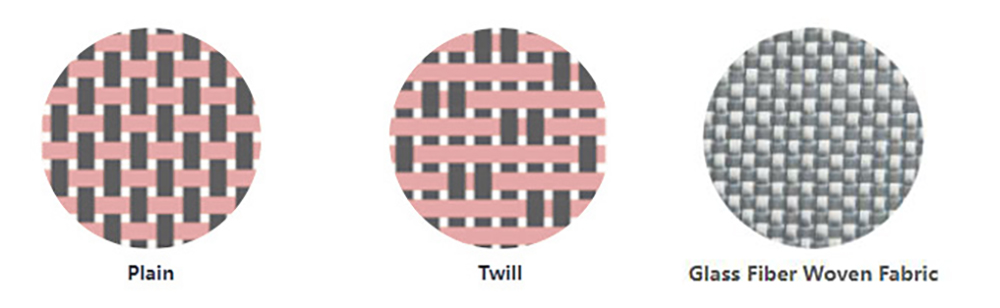

E-glass-ka dharka tolka ah waxaa lagu sameeyaa iyadoo la is dhex galiyay maro toosan iyo kuwo taagan ama rovings. Codsiyada ugu muhiimsan waxay daboolayaan meelaha sida godadka doonyaha, qalabka isboortiga, qaybaha milatariga, iyo warshadaha baabuurta, iyo kuwo kale.

Astaamaha

●Waxay muujisaa waafaqid xooggan UP, VE, iyo EP.

●Sifooyin farsamo oo heersare ah

●Joogteynta qaabdhismeedka heersare ah

●Soo bandhigidda dusha sare ee heersare ah

Tilmaamaha

| Spec No. | Dhismaha | Cufnaanta (dhammaado/cm) | Cuf (g/m2) | Xoogga Jilicsan | Tex | |||||||||

| Warp | Dufan | Warp | Dufan | Warp | Dufan | |||||||||

| EW60 | Cad | 20 | ± | 2 | 20 | ± | 2 | 48 | ± | 4 | ≥260 | ≥260 | 12.5 | 12.5 |

| EW80 | Cad | 12 | ± | 1 | 12 | ± | 1 | 80 | ± | 8 | ≥300 | ≥300 | 33 | 33 |

| EWT80 | Twill | 12 | ± | 2 | 12 | ± | 2 | 80 | ± | 8 | ≥300 | ≥300 | 33 | 33 |

| EW100 | Cad | 16 | ± | 1 | 15 | ± | 1 | 110 | ± | 10 | ≥400 | ≥400 | 33 | 33 |

| EWT100 | Twill | 16 | ± | 1 | 15 | ± | 1 | 110 | ± | 10 | ≥400 | ≥400 | 33 | 33 |

| EW130 | Cad | 10 | ± | 1 | 10 | ± | 1 | 130 | ± | 10 | ≥600 | ≥600 | 66 | 66 |

| EW160 | Cad | 12 | ± | 1 | 12 | ± | 1 | 160 | ± | 12 | ≥700 | ≥650 | 66 | 66 |

| EWT160 | Twill | 12 | ± | 1 | 12 | ± | 1 | 160 | ± | 12 | ≥700 | ≥650 | 66 | 66 |

| EW200 | Cad | 8 | ± | 0.5 | 7 | ± | 0.5 | 198 | ± | 14 | ≥650 | ≥550 | 132 | 132 |

| EW200 | Cad | 16 | ± | 1 | 13 | ± | 1 | 200 | ± | 20 | ≥700 | ≥650 | 66 | 66 |

| EWT200 | Twill | 16 | ± | 1 | 13 | ± | 1 | 200 | ± | 20 | ≥900 | ≥700 | 66 | 66 |

| EW300 | Cad | 8 | ± | 0.5 | 7 | ± | 0.5 | 300 | ± | 24 | ≥1000 | ≥800 | 200 | 200 |

| EWT300 | Twill | 8 | ± | 0.5 | 7 | ± | 0.5 | 300 | ± | 24 | ≥1000 | ≥800 | 200 | 200 |

| EW400 | Cad | 8 | ± | 0.5 | 7 | ± | 0.5 | 400 | ± | 32 | ≥1200 | ≥1100 | 264 | 264 |

| EWT400 | Twill | 8 | ± | 0.5 | 7 | ± | 0.5 | 400 | ± | 32 | ≥1200 | ≥1100 | 264 | 264 |

| EW400 | Cad | 6 | ± | 0.5 | 6 | ± | 0.5 | 400 | ± | 32 | ≥1200 | ≥1100 | 330 | 330 |

| EWT400 | Twill | 6 | ± | 0.5 | 6 | ± | 0.5 | 400 | ± | 32 | ≥1200 | ≥1100 | 330 | 330 |

| WR400 | Cad | 3.4 | ± | 0.3 | 3.2 | ± | 0.3 | 400 | ± | 32 | ≥1200 | ≥1100 | 600 | 600 |

| WR500 | Cad | 2.2 | ± | 0.2 | 2 | ± | 0.2 | 500 | ± | 40 | ≥1600 | ≥1500 | 1200 | 1200 |

| WR600 | Cad | 2.5 | ± | 0.2 | 2.5 | ± | 0.2 | 600 | ± | 48 | ≥2000 | ≥1900 | 1200 | 1200 |

| WR800 | Cad | 1.8 | ± | 0.2 | 1.6 | ± | 0.2 | 800 | ± | 64 | ≥2300 | ≥2200 | 2400 | 2400 |

Baakadaha

● Dhexroorka duubka Fiberglass Tolsan wuxuu noqon karaa 28cm ilaa duub jumbo.

● Duubabka waxaa lagu duubaa xudunta warqadda oo leh dhexroor gudaha ah 76.2mm(3 inch) ama 101.6mm (4 inch).

● Duub kasta waxaa lagu duuduubay bac ama filim ka dibna waxaa lagu shubaa kartoon.

● Duubabka ayaa si toosan ama toosan u dulsaaran sariiraha.

Kaydinta

● Xaaladda jawiga: bakhaar qabow & qalalan ayaa lagula talinayaa

● Heerkulka ugu fiican ee kaydinta: 15 ℃ ~ 35 ℃

● Qoyaanka ugu wanaagsan ee kaydinta: 35% ~ 75%.

●Si loo kordhiyo waxqabadkeeda, sariirta waa in lagu xidho goobta shaqada ugu yaraan 24 saacadood ka hor inta aan la isticmaalin.

● Marka qayb ka mid ah waxa ku jira cutubka la isticmaalo, unugga waa in la xidhaa ka hor isticmaalka xiga.