Maro Fiberglass ah Oo Si Balaadhan Loo Isticmaalay iyo Wadista Wadnaha

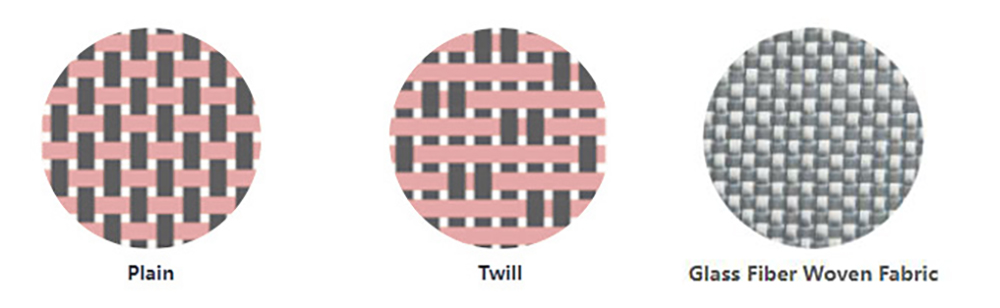

E-glass-ka dharka tolan waxa uu leeyahay qaab-dhismeed isku dheeli tiran oo xagal orthogonal ah oo uu ka samaysan yahay dagaal isku xidhan iyo rovings. Qalabkan xoojinta laba jiho ayaa si weyn looga isticmaalaa nidaamyada difaaca ee codsiyada badda, qaybaha baabuurta, iyo wax soo saarka qalabka isboortiga ee waxqabadka sarreeya.

Astaamaha

●Waafaqid aad u wanaagsan UP/VE/EP

●Hanti farsamo oo heer sare ah

●Degenaansho qaabdhismeed heer sare ah

●muuqaalka kore ee heer sare ah

Tilmaamaha

| Spec No. | Dhismaha | Cufnaanta (dhammaado/cm) | Cuf (g/m2) | Xoogga Jilicsan | Tex | |||||||||

| Warp | Dufan | Warp | Dufan | Warp | Dufan | |||||||||

| EW60 | Cad | 20 | ± | 2 | 20 | ± | 2 | 48 | ± | 4 | ≥260 | ≥260 | 12.5 | 12.5 |

| EW80 | Cad | 12 | ± | 1 | 12 | ± | 1 | 80 | ± | 8 | ≥300 | ≥300 | 33 | 33 |

| EWT80 | Twill | 12 | ± | 2 | 12 | ± | 2 | 80 | ± | 8 | ≥300 | ≥300 | 33 | 33 |

| EW100 | Cad | 16 | ± | 1 | 15 | ± | 1 | 110 | ± | 10 | ≥400 | ≥400 | 33 | 33 |

| EWT100 | Twill | 16 | ± | 1 | 15 | ± | 1 | 110 | ± | 10 | ≥400 | ≥400 | 33 | 33 |

| EW130 | Cad | 10 | ± | 1 | 10 | ± | 1 | 130 | ± | 10 | ≥600 | ≥600 | 66 | 66 |

| EW160 | Cad | 12 | ± | 1 | 12 | ± | 1 | 160 | ± | 12 | ≥700 | ≥650 | 66 | 66 |

| EWT160 | Twill | 12 | ± | 1 | 12 | ± | 1 | 160 | ± | 12 | ≥700 | ≥650 | 66 | 66 |

| EW200 | Cad | 8 | ± | 0.5 | 7 | ± | 0.5 | 198 | ± | 14 | ≥650 | ≥550 | 132 | 132 |

| EW200 | Cad | 16 | ± | 1 | 13 | ± | 1 | 200 | ± | 20 | ≥700 | ≥650 | 66 | 66 |

| EWT200 | Twill | 16 | ± | 1 | 13 | ± | 1 | 200 | ± | 20 | ≥900 | ≥700 | 66 | 66 |

| EW300 | Cad | 8 | ± | 0.5 | 7 | ± | 0.5 | 300 | ± | 24 | ≥1000 | ≥800 | 200 | 200 |

| EWT300 | Twill | 8 | ± | 0.5 | 7 | ± | 0.5 | 300 | ± | 24 | ≥1000 | ≥800 | 200 | 200 |

| EW400 | Cad | 8 | ± | 0.5 | 7 | ± | 0.5 | 400 | ± | 32 | ≥1200 | ≥1100 | 264 | 264 |

| EWT400 | Twill | 8 | ± | 0.5 | 7 | ± | 0.5 | 400 | ± | 32 | ≥1200 | ≥1100 | 264 | 264 |

| EW400 | Cad | 6 | ± | 0.5 | 6 | ± | 0.5 | 400 | ± | 32 | ≥1200 | ≥1100 | 330 | 330 |

| EWT400 | Twill | 6 | ± | 0.5 | 6 | ± | 0.5 | 400 | ± | 32 | ≥1200 | ≥1100 | 330 | 330 |

| WR400 | Cad | 3.4 | ± | 0.3 | 3.2 | ± | 0.3 | 400 | ± | 32 | ≥1200 | ≥1100 | 600 | 600 |

| WR500 | Cad | 2.2 | ± | 0.2 | 2 | ± | 0.2 | 500 | ± | 40 | ≥1600 | ≥1500 | 1200 | 1200 |

| WR600 | Cad | 2.5 | ± | 0.2 | 2.5 | ± | 0.2 | 600 | ± | 48 | ≥2000 | ≥1900 | 1200 | 1200 |

| WR800 | Cad | 1.8 | ± | 0.2 | 1.6 | ± | 0.2 | 800 | ± | 64 | ≥2300 | ≥2200 | 2400 | 2400 |

Baakadaha

● Darigeena fiberglass-ka tolan wuxuu ku yimaadaa dhexroor duuban oo kala duwan, laga bilaabo 28cm ilaa duubka jumbo ee cabbirka warshadaha.

● Duubabka waxaa lagu duubaa xudunta warqadda oo leh dhexroor gudaha ah 76.2mm(3 inch) ama 101.6mm (4 inch).

● Duub kasta oo fiberglass ah si gaar ah ayaa loogu shaabadeeyey filim caag ah oo ilaalinaya waxaana si ammaan ah loogu baakeeyey sanduuqyo kartoon oo la xoojiyay

● Duubabka ayaa si toosan ama toosan u dulsaaran sariiraha.

Kaydinta

● Xaaladda jawiga: bakhaar qabow & qalalan ayaa lagula talinayaa

● Heerkulka ugu fiican ee kaydinta: 15 ℃ ~ 35 ℃

● Qoyaanka ugu wanaagsan ee kaydinta: 35% ~ 75%.

● Qaboojinta goobta shaqada ee saxda ah (ugu yaraan 24 saacadood) ayaa loo baahan yahay si loo hubiyo xasilloonida cabbirka iyo waxqabadka isku xidhka ugu wanaagsan

● Haddii waxa ku jira cutubka qayb ahaan la isticmaalo, unugga waa in la xidhaa ka hor isticmaalka dambe.