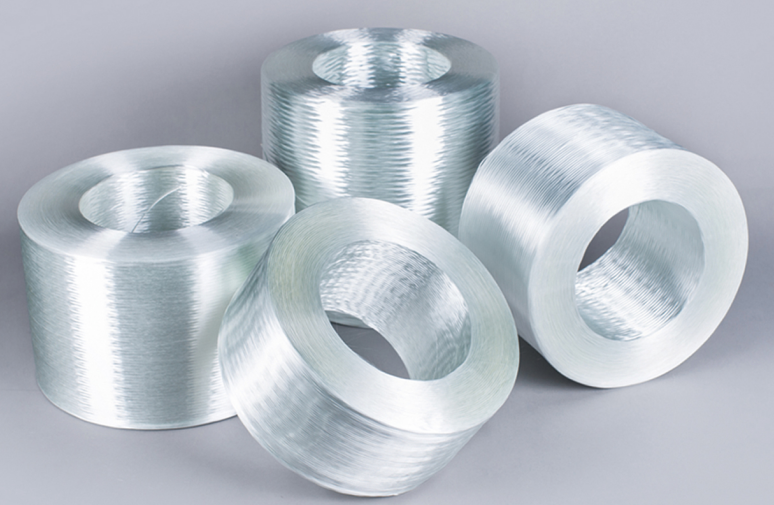

Glass fiber yarn plays a crucial role in numerous industrial applications, with non-twisted glass fiber roving being a key variant that caters to specific manufacturing needs. Among them, the non-twisted glass fiber roving designed for pultrusion, winding, and textile processes stands out for its exceptional performance.

The HCR3027 series of alkali-free glass fiber non-twisted roving adopts a boron-free and fluorine-free formula, making it highly suitable for pultrusion, winding, and weaving techniques. This series exhibits excellent compatibility with a wide range of resins, including unsaturated polyester resin, vinyl resin, phenolic resin, epoxy resin, and polyurethane resin. Such versatility allows its products to be widely used in diverse fields. In the construction industry, they find application in various structural components; in rail transit, they contribute to the manufacturing of durable parts; for rail anti-corrosion, they provide reliable protection; they are also used in storage tanks, profiles, and sports equipment, among other areas.

Another important category is the non-twisted glass fiber roving dedicated to thermoplastic products. The HCR5018S/5019 series of alkali-free glass fiber non-twisted roving is an ideal reinforcing material for thermoplastics. Its surface is coated with a silane-based sizing agent, which ensures good compatibility with matrix resins. It is suitable for reinforcing thermoplastics such as PA, PP, PBT, PET, and AS/ABS. This makes it a preferred choice in many industries. In the automotive sector, it is used in the production of various car parts, enhancing their strength and durability; in electronic and electrical products, it provides reliable reinforcement for components; it is also applied in mechanical tools and sports goods, improving their performance and lifespan.

These glass fiber yarn products, with their unique properties and wide-ranging applications, continue to drive innovation and development in multiple industries. Their ability to enhance the performance of various materials makes them indispensable in modern manufacturing processes, contributing to the creation of high-quality and long-lasting products.

Post time: Jul-22-2025