Multi-Purpose Combo Mats for Every Environment

Stitched mat

Description

Stitched mat is fabricated by systematically arranging chopped fiber strands of defined lengths into a uniform layer, which is subsequently bound together using polyester stitching threads. The fiberglass strands are treated with a silane coupling agent within their sizing chemistry, ensuring adhesion compatibility with resins such as unsaturated polyester, vinyl ester, epoxy, and related systems. This homogeneous fiber alignment delivers consistent material stability and robust mechanical performance.

Features

1. Consistent grammage and dimensional uniformity, enhanced structural cohesion, and elimination of fiber shedding.

2.Fast wet-out

3. Good compatibility

4.Ideal for specifications highlighting material performance in composite layup or thermoforming processes.

5.Easy to split

6.Surface aesthetics

7.Good mechanical properties

|

Product code |

Width(mm) |

Unit weight(g/㎡) |

Moisture Content(%) |

|

SM300/380/450 |

100-1270 |

300/380/450 |

≤0.2 |

Combo mat

Description

Fiberglass composite mats integrate multiple fiberglass material types through manufacturing processes such as knitting, needling, or binder bonding. This multicomponent integration provides engineered versatility, exceptional formability, and broad compatibility with diverse application requirements.

Features & benefits

1. Fiberglass composite mats can be customized by selecting distinct fiberglass materials and manufacturing techniques (e.g., knitting, needling, or binder bonding), allowing optimization for diverse processes such as pultrusion, resin transfer molding (RTM), and vacuum infusion. Their enhanced conformability enables seamless adaptation to intricate mold geometries.

2. Can be customized to meet specific strength or appearance requirements.

3. Reduced pre-mold dressing and tailoring, increased productivity

4. Efficient use of material and labor cost

|

Products |

Description |

|

|

WR +CSM (Stitched or needled) |

Complexes are typically a combination of Woven Roving (WR) and chopped strands assembled by stitching or needling. |

|

|

CFM Complex |

CFM + Veil |

a complex product composed by a layer of Continuous Filaments and a layer of veil, stitched or bonded together |

|

CFM + knitted Fabric |

This complex is obtained by sewing a central layer of continuous filament mat with knitted fabrics on one or both sides CFM as the flow media |

|

|

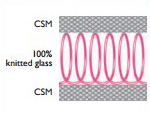

Sandwich Mat |

|

Designed for RTM closed mold applications. 100% glass 3-Dimensional complex combination of a knitted glass fiber core that is stitch bonded between two layers of binder free chopped glass. |