Pannus Vitreus Fiberatus et Textura Roving

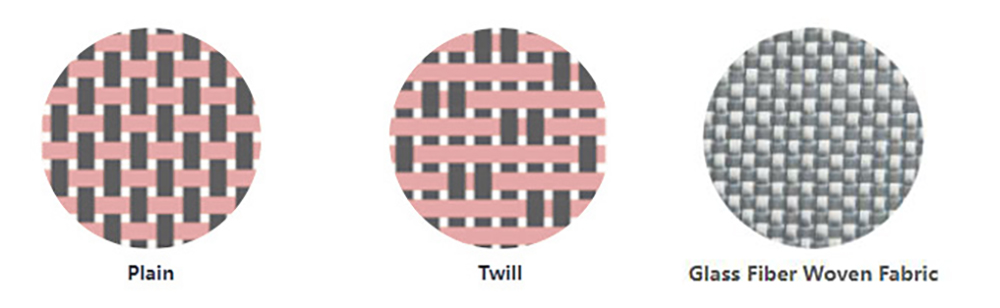

Textura vitrea electronica filis/stratulis horizontalibus et verticalibus intertexitur. Praecipue in corporibus navium, mechanicis athleticis, rebus militaribus, autocinetis, et cetera adhibetur.

Proprietates

●Excellens compatibilitas cum UP/VE/EP

●Proprietates mechanicae excellentes

●Excellens stabilitas structurae

●Aspectus superficialis excellens

Specificationes

| Numerus Specificationis | Constructio | Densitas (extremitates/cm) | Massa (g/m²) | Robur Tensilis | Tex | |||||||||

| Stamina | Trama | Stamina | Trama | Stamina | Trama | |||||||||

| EW60 | Planus | 20 | ± | 2 | 20 | ± | 2 | 48 | ± | 4 | ≥260 | ≥260 | 12.5 | 12.5 |

| EW80 | Planus | 12 | ± | 1 | 12 | ± | 1 | 80 | ± | 8 | ≥300 | ≥300 | 33 | 33 |

| EWT80 | Sarga | 12 | ± | 2 | 12 | ± | 2 | 80 | ± | 8 | ≥300 | ≥300 | 33 | 33 |

| EW100 | Planus | 16 | ± | 1 | 15 | ± | 1 | 110 | ± | 10 | ≥400 | ≥400 | 33 | 33 |

| EWT100 | Sarga | 16 | ± | 1 | 15 | ± | 1 | 110 | ± | 10 | ≥400 | ≥400 | 33 | 33 |

| EW130 | Planus | 10 | ± | 1 | 10 | ± | 1 | 130 | ± | 10 | ≥600 | ≥600 | 66 | 66 |

| EW160 | Planus | 12 | ± | 1 | 12 | ± | 1 | CLX | ± | 12 | ≥700 | ≥650 | 66 | 66 |

| EWT160 | Sarga | 12 | ± | 1 | 12 | ± | 1 | CLX | ± | 12 | ≥700 | ≥650 | 66 | 66 |

| EW200 | Planus | 8 | ± | 0.5 | 7 | ± | 0.5 | 198 | ± | 14 | ≥650 | ≥550 | 132 | 132 |

| EW200 | Planus | 16 | ± | 1 | 13 | ± | 1 | ducenti | ± | 20 | ≥700 | ≥650 | 66 | 66 |

| EWT200 | Sarga | 16 | ± | 1 | 13 | ± | 1 | ducenti | ± | 20 | ≥900 | ≥700 | 66 | 66 |

| EW300 | Planus | 8 | ± | 0.5 | 7 | ± | 0.5 | trecenti | ± | 24 | ≥1000 | ≥800 | ducenti | ducenti |

| EWT300 | Sarga | 8 | ± | 0.5 | 7 | ± | 0.5 | trecenti | ± | 24 | ≥1000 | ≥800 | ducenti | ducenti |

| EW400 | Planus | 8 | ± | 0.5 | 7 | ± | 0.5 | quadringenti | ± | 32 | ≥1200 | ≥1100 | 264 | 264 |

| EWT400 | Sarga | 8 | ± | 0.5 | 7 | ± | 0.5 | quadringenti | ± | 32 | ≥1200 | ≥1100 | 264 | 264 |

| EW400 | Planus | 6 | ± | 0.5 | 6 | ± | 0.5 | quadringenti | ± | 32 | ≥1200 | ≥1100 | 330 | 330 |

| EWT400 | Sarga | 6 | ± | 0.5 | 6 | ± | 0.5 | quadringenti | ± | 32 | ≥1200 | ≥1100 | 330 | 330 |

| WR400 | Planus | 3.4 | ± | 0.3 | 3.2 | ± | 0.3 | quadringenti | ± | 32 | ≥1200 | ≥1100 | DC | DC |

| WR500 | Planus | 2.2 | ± | 0.2 | 2 | ± | 0.2 | quingenti | ± | 40 | ≥1600 | ≥1500 | 1200 | 1200 |

| WR600 | Planus | 2.5 | ± | 0.2 | 2.5 | ± | 0.2 | DC | ± | 48 | ≥2000 | ≥1900 | 1200 | 1200 |

| WR800 | Planus | 1.8 | ± | 0.2 | 1.6 | ± | 0.2 | DCCC | ± | 64 | ≥2300 | ≥2200 | 2400 | 2400 |

Involucrum

● Diameter voluminis mattae vitreae consutae a 28cm ad volumen ingens esse potest.

● Volumen cum nucleo chartaceo convolvitur, cuius diametrus internae 76.2 mm (3 unciarum) vel 101.6 mm (4 unciarum) sunt.

● Quaeque volumina in sacculo plastico vel pellicula involuta, deinde in capsa chartacea condiuntur.

● Rotuli in palletis verticaliter vel horizontaliter conguntur.

Depositorium

● Conditio ambientis: horreum frigidum et sicum commendatur.

● Temperatura optima repositionis: 15℃ ~ 35℃

● Humiditas optima repositionis: 35% ~ 75%.

● Ante usum, matta in loco laboris per viginti quattuor horas saltem condicionem adhibere debet ut efficacia optimizetur.

● Si contenta involucri partim adhibita sunt, unitas ante proximum usum claudi debet.