Kain Fiberglass sing Digunakake lan Tenun Roving

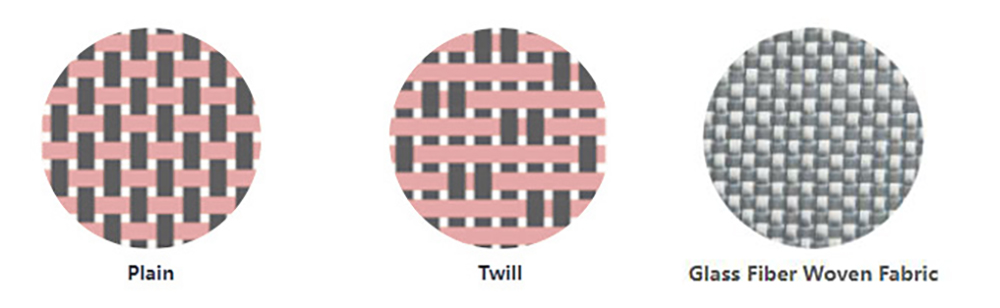

Kain tenunan kaca e-kaca nduweni struktur kisi ortogonal sing seimbang sing dibentuk dening rovings warp lan weft interlaced. Materi penguatan bidirectional iki akeh digunakake ing sistem pertahanan aplikasi laut, komponen otomotif, lan manufaktur peralatan olahraga kanthi kinerja dhuwur.

Fitur

●Kompatibilitas banget karo UP / VE / EP

●Sifat mekanik sing apik banget

●Stabilitas struktur sing apik banget

●Tampilan permukaan sing apik banget

Spesifikasi

| Spesifikasi No. | Konstruksi | Kapadhetan (ends / cm) | Massa (g/m2) | Kekuwatan Tensile | Tex | |||||||||

| Warp | Weft | Warp | Weft | Warp | Weft | |||||||||

| EW60 | Plain | 20 | ± | 2 | 20 | ± | 2 | 48 | ± | 4 | ≥260 | ≥260 | 12.5 | 12.5 |

| EW80 | Plain | 12 | ± | 1 | 12 | ± | 1 | 80 | ± | 8 | ≥300 | ≥300 | 33 | 33 |

| EWT80 | kepar | 12 | ± | 2 | 12 | ± | 2 | 80 | ± | 8 | ≥300 | ≥300 | 33 | 33 |

| EW100 | Plain | 16 | ± | 1 | 15 | ± | 1 | 110 | ± | 10 | ≥400 | ≥400 | 33 | 33 |

| EWT100 | kepar | 16 | ± | 1 | 15 | ± | 1 | 110 | ± | 10 | ≥400 | ≥400 | 33 | 33 |

| EW130 | Plain | 10 | ± | 1 | 10 | ± | 1 | 130 | ± | 10 | ≥600 | ≥600 | 66 | 66 |

| EW160 | Plain | 12 | ± | 1 | 12 | ± | 1 | 160 | ± | 12 | ≥700 | ≥650 | 66 | 66 |

| EWT160 | kepar | 12 | ± | 1 | 12 | ± | 1 | 160 | ± | 12 | ≥700 | ≥650 | 66 | 66 |

| EW200 | Plain | 8 | ± | 0.5 | 7 | ± | 0.5 | 198 | ± | 14 | ≥650 | ≥550 | 132 | 132 |

| EW200 | Plain | 16 | ± | 1 | 13 | ± | 1 | 200 | ± | 20 | ≥700 | ≥650 | 66 | 66 |

| EWT200 | kepar | 16 | ± | 1 | 13 | ± | 1 | 200 | ± | 20 | ≥900 | ≥700 | 66 | 66 |

| EW300 | Plain | 8 | ± | 0.5 | 7 | ± | 0.5 | 300 | ± | 24 | ≥1000 | ≥800 | 200 | 200 |

| EWT300 | kepar | 8 | ± | 0.5 | 7 | ± | 0.5 | 300 | ± | 24 | ≥1000 | ≥800 | 200 | 200 |

| EW400 | Plain | 8 | ± | 0.5 | 7 | ± | 0.5 | 400 | ± | 32 | ≥1200 | ≥1100 | 264 | 264 |

| EWT400 | kepar | 8 | ± | 0.5 | 7 | ± | 0.5 | 400 | ± | 32 | ≥1200 | ≥1100 | 264 | 264 |

| EW400 | Plain | 6 | ± | 0.5 | 6 | ± | 0.5 | 400 | ± | 32 | ≥1200 | ≥1100 | 330 | 330 |

| EWT400 | kepar | 6 | ± | 0.5 | 6 | ± | 0.5 | 400 | ± | 32 | ≥1200 | ≥1100 | 330 | 330 |

| WR400 | Plain | 3.4 | ± | 0.3 | 3.2 | ± | 0.3 | 400 | ± | 32 | ≥1200 | ≥1100 | 600 | 600 |

| WR500 | Plain | 2.2 | ± | 0.2 | 2 | ± | 0.2 | 500 | ± | 40 | ≥1600 | ≥1500 | 1200 | 1200 |

| WR600 | Plain | 2.5 | ± | 0.2 | 2.5 | ± | 0.2 | 600 | ± | 48 | ≥2000 | ≥1900 | 1200 | 1200 |

| WR800 | Plain | 1.8 | ± | 0.2 | 1.6 | ± | 0.2 | 800 | ± | 64 | ≥2300 | ≥2200 | 2400 | 2400 |

Kemasan

● Tikar jahitan fiberglass kita kasedhiya ing macem-macem diameter gulungan, wiwit saka 28cm nganti gulungan jumbo ukuran industri..

● Gulung kasebut digulung nganggo inti kertas sing diametere jero 76.2mm (3 inci) utawa 101.6mm (4 inci).

● Saben gulungan fiberglass disegel kanthi individu ing film plastik protèktif lan dibungkus kanthi aman ing kothak karton sing dikuatake.

● Gulungan ditumpuk vertikal utawa horisontal ing palet.

Panyimpenan

● Kondisi sekitar: gudang sing adhem lan garing dianjurake

● Suhu panyimpenan optimal: 15 ℃ ~ 35 ℃

● Kelembapan panyimpenan optimal: 35% ~ 75%.

● Kondisi papan kerja sing tepat (minimal 24 jam) dibutuhake kanggo njamin stabilitas dimensi lan kinerja ikatan sing optimal

● Yen isi unit paket digunakake sebagian, unit kasebut kudu ditutup sadurunge digunakake sabanjure.