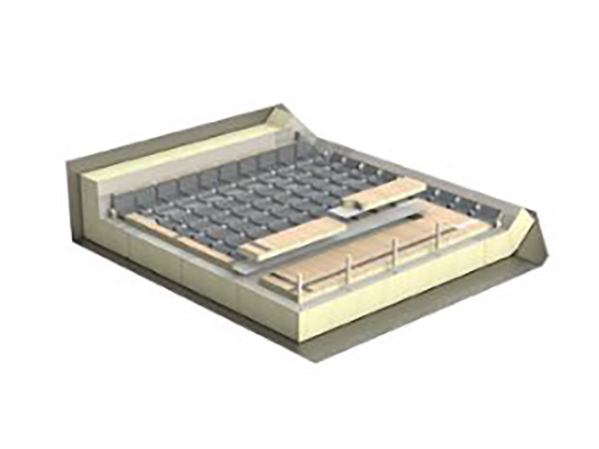

Sab saum toj Nruam Filament Mat rau PU Foaming Efficiency

NTA & KHOOM

●Cov ntsiab lus binder tsawg tsawg

●Tsis muaj zog interlayer bonding

●Txo filament suav rau ib pob

KHOOM PLIG

| Khoom Code | Qhov hnyav (g) | Max dav (cm) | Solubility nyob rau hauv styrene | Bundle ceev (tex) | Cov ntsiab lus ruaj khov | Resin compatibility | Txheej txheem |

| CFM981-450 | 450 | 260 | qis | 20 | 1.1 ± 0.5 | PU | PU ua npuas ncauj |

| CFM983-450 | 450 | 260 | qis | 20 | 2.5 ± 0.5 | PU | PU ua npuas ncauj |

●Lwm qhov hnyav muaj nyob ntawm qhov kev thov.

●Lwm qhov dav muaj raws li qhov kev thov.

●CFM981's ultra-low binder formulation enables uniform dispersion nyob rau hauv PU ua npuas ncauj thaum lub sij hawm nthuav dav, ua rau nws qhov zoo tshaj plaws kev daws teeb meem rau LNG cab kuj rwb thaiv tsev panels.

Ntim

●Cov tub ntxhais sab hauv yog muaj nyob rau hauv ob txoj kab uas hla: 3 "(76.2mm) lossis 4" (102mm), muaj qhov tsawg kawg nkaus 3 hli phab ntsa tuab rau kev ua haujlwm zoo.

●Tag nrho cov yob thiab pallets yog shrink-pob nrog zaj duab xis tiv thaiv kom tsis txhob raug plua plav, ya raws, thiab lub cev puas tsuaj thaum thauj mus los thiab warehouses.

●Peb cov ntawv sau npe ntse muab kev nkag mus rau cov ntaub ntawv tseem ceeb (qhov hnyav, qhov ntau, hnub tsim khoom) los ntawm cov cim barcodes ntawm txhua chav tsev, ua kom zoo rau kev tswj hwm tsev rau khoom thiab nrhiav cov khoom.

NTAU

●Pom zoo cia cov xwm txheej: CFM yuav tsum tau khaws cia rau hauv qhov chaw txias, qhuav kom ruaj khov thiab ua haujlwm zoo.

●Optimum cia kub ntau yam: 15 ℃ to 35 ℃ los tiv thaiv cov khoom degradation.

●Qhov zoo tshaj plaws cia cov av noo ntau: 35% mus rau 75% kom tsis txhob muaj cov dej noo ntau dhau los yog qhuav uas yuav cuam tshuam rau kev tuav thiab siv.

●Pallet stacking: Nws raug nquahu kom muab cov pallets tso rau hauv qhov siab kawg ntawm 2 txheej txhawm rau tiv thaiv deformation lossis compression puas.

●Pre-siv txias: Ua ntej daim ntawv thov, lub lev yuav tsum conditioned nyob rau hauv lub chaw ua hauj lwm ib puag ncig yam tsawg kawg yog 24 teev kom ua tau zoo ntawm kev ua tau zoo.

●Cov pob khoom siv ib nrab: Yog tias cov ntsiab lus ntawm lub ntim ntim tau siv ib nrab, lub pob yuav tsum tau muab rov qab kom zoo thiab tiv thaiv kom tsis txhob muaj kab mob los yog nqus dej ua ntej siv tom ntej.