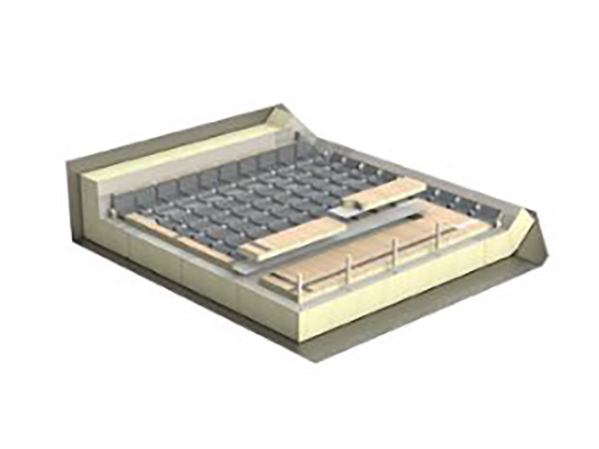

High-Quality Nruam Filament Mat rau PU Foam Daim Ntawv Thov

NTA & KHOOM

●Cov ntsiab lus binder tsawg heev

●Tsawg kev ncaj ncees ntawm cov khaubncaws sab nraud povtseg ntawm lev

●Tsawg pob linear ceev

KHOOM PLIG

| Khoom Code | Qhov hnyav (g) | Max dav (cm) | Solubility nyob rau hauv styrene | Bundle ceev (tex) | Cov ntsiab lus ruaj khov | Resin compatibility | Txheej txheem |

| CFM981-450 | 450 | 260 | qis | 20 | 1.1 ± 0.5 | PU | PU ua npuas ncauj |

| CFM983-450 | 450 | 260 | qis | 20 | 2.5 ± 0.5 | PU | PU ua npuas ncauj |

●Lwm qhov hnyav muaj nyob ntawm qhov kev thov.

●Lwm qhov dav muaj raws li qhov kev thov.

●CFM981 nta tshwj xeeb uas tsis tshua muaj binder concentration, ua kom muaj kev faib tawm hauv cov polyurethane matrix thoob plaws hauv cov txheej txheem foaming. Cov yam ntxwv no tsim nws los ua qhov kev daws teeb meem zoo tshaj plaws rau kev siv rwb thaiv tsev hauv cov roj liquefied natural gas (LNG).

Ntim

●Sab hauv cov kev xaiv: Muaj nyob rau hauv 3 "(76.2mm) los yog 4" (102mm) diameters nrog rau qhov tsawg kawg nkaus phab ntsa thickness ntawm 3 hli, kom muaj zog txaus thiab ruaj khov.

●Kev Tiv Thaiv Ntim:Txhua yob thiab pallet tau txais ib tus neeg encapsulation siv cov yeeb yaj kiab tiv thaiv siab, txo cov kev pheej hmoo ntawm kev puas tsuaj ntawm lub cev, kev sib kis kab mob, thiab cov av noo nkag mus rau hauv kev thauj mus los thiab cov khoom lag luam. Cov txheej txheem no ua kom muaj kev ruaj ntseg ruaj ntseg thiab tswj kev sib kis, tseem ceeb heev rau kev tswj cov khoom lag luam zoo hauv kev xav tau ib puag ncig logistics.

●Labeling & Traceability: Txhua yob thiab pallet tau sau nrog cov ntaub ntawv pov thawj uas muaj cov ntaub ntawv tseem ceeb xws li qhov hnyav, tus naj npawb ntawm cov yob, hnub tsim khoom, thiab lwm yam ntaub ntawv tseem ceeb rau kev taug qab thiab kev tswj cov khoom muag.

NTAU

●Pom zoo cia cov xwm txheej: CFM yuav tsum tau khaws cia rau hauv qhov chaw txias, qhuav kom ruaj khov thiab ua haujlwm zoo.

●Optimum cia kub ntau yam: 15 ℃ to 35 ℃ los tiv thaiv cov khoom degradation.

●Qhov zoo tshaj plaws cia cov av noo ntau: 35% mus rau 75% kom tsis txhob muaj cov dej noo ntau dhau los yog qhuav uas yuav cuam tshuam rau kev tuav thiab siv.

●Pallet stacking: Nws raug nquahu kom muab cov pallets tso rau hauv qhov siab kawg ntawm 2 txheej txhawm rau tiv thaiv deformation lossis compression puas.

●Pre-siv txias: Ua ntej daim ntawv thov, lub lev yuav tsum conditioned nyob rau hauv lub chaw ua hauj lwm ib puag ncig yam tsawg kawg yog 24 teev kom ua tau zoo ntawm kev ua tau zoo.

●Cov pob khoom siv ib nrab: Yog tias cov ntsiab lus ntawm lub ntim ntim tau siv ib nrab, lub pob yuav tsum tau muab rov qab kom zoo thiab tiv thaiv kom tsis txhob muaj kab mob los yog nqus dej ua ntej siv tom ntej.