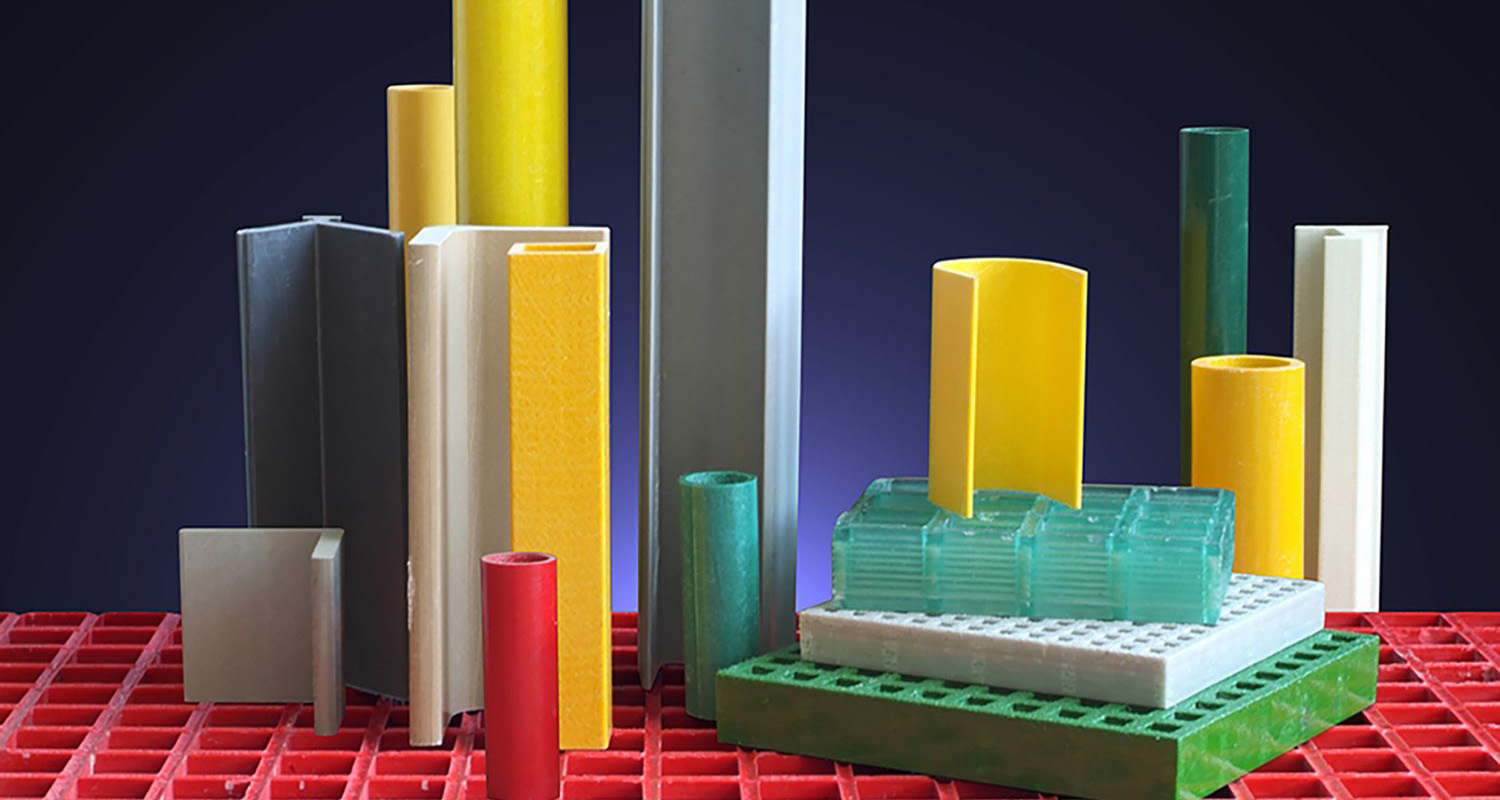

Fiberglass Continuous Filament Mat: Txhim kho koj cov khoom ua haujlwm ntev

Jiuding feem ntau muaj plaub pawg ntawm CFM

CFM rau Pultrusion

Kev piav qhia

CFM955 yog ib lub lev ua tau zoo tsim los rau cov txheej txheem pultrusion. Nws nta nrawm ntub-dhau, zoo ntub-tawm, siab tensile zog, zoo conformability, thiab txhawb nqa ib tug du nto tiav ntawm profiles.

Nta & Cov txiaj ntsig

● Muab lub zog tensile siab txawm tias thaum resin-impregnated thiab nyob rau ntawm qhov kub thiab txias, lub lev no yog tsim los rau cov voj voog ntau lawm thiab muaj peev xwm ua tau raws li qhov yuav tsum tau muaj kev tsim khoom siab.

● Ib qho yooj yim resin ntws-los ntawm thiab ua tiav fiber ntau encapsulation.

● Tsim kom muaj txiaj ntsig slitting rau ntau qhov ntau thiab tsawg, txo cov khib nyiab thiab poob qis.

● Muab lub zog siab nyob rau hauv cov lus qhia transverse thiab random rau pultruded profiles.

● Muab cov machinability zoo heev rau kev yooj yim ntawm fabrication thiab tom qab ua tiav.

CFM rau kaw Moulding

Kev piav qhia

CFM985 excels infusion, RTM, S-RIM, thiab compression txheej txheem. Nws qhov txiaj ntsig tseem ceeb yog nyob rau hauv nws cov yam ntxwv zoo tshaj plaws, tso cai rau nws siv tsis yog rau kev txhawb nqa xwb tab sis kuj yog txoj hauv kev zoo ntws ntawm cov khaubncaws sab nraud povtseg ntawm cov ntaub.

Nta & Cov txiaj ntsig

● Ua kom tiav resin saturation nrog tsawg voids.

● Cov tshuaj tiv thaiv zoo heev rau kev ntxuav.

● Superior pwm conformity.

● Cov khoom siv yooj yim uas yooj yim rau unroll, txiav kom loj, thiab tuav hauv khw hauv pem teb.

CFM rau Preforming

Kev piav qhia

CFM828 yog tsim tshwj xeeb rau kev tsim khoom ua ntej hauv cov txheej txheem kaw-pwm suav nrog cov hloov pauv hloov pwm (siab thiab tsis tshua muaj siab), nqus dej infusion, thiab compression molding. Cov thermoplastic hmoov binder ua ke ua kom muaj qhov tshwj xeeb deformability thiab txhim kho cov yam ntxwv ntawm kev ua haujlwm ua ntej. Cov khoom siv no yog siv dav hauv kev tsim cov khoom siv rau cov tsheb thauj khoom hnyav, tsheb sib dhos, thiab cov khoom siv hauv tsev.

Raws li cov ntaub ntawv txuas ntxiv mus, CFM828 muab cov kev xaiv zoo tshaj plaws rau kev tsim cov pwm tsim.

Nta & Cov txiaj ntsig

● Khaws cov khoom seem uas pom zoo ntawm cov pwm nto.

● Optimal flow yam ntxwv

● Ua kom muaj zog thiab ua haujlwm ntev dua

● Qhia txog kev coj tus cwj pwm zoo heev thiab tuaj yeem txiav kom huv si thiab ua haujlwm yooj yim.

CFM rau PU Foaming

Kev piav qhia

CFM981 tshwj xeeb yog tsim los ua cov khoom siv kho kom zoo hauv polyurethane ua npuas ncauj panels. Nws cov yam ntxwv uas tsis tshua muaj binder cov ntsiab lus txhawb nqa kev sib txawv tsis sib xws thoob plaws hauv kev nthuav dav PU matrix, kom ntseeg tau tias muaj kev sib koom ua ke ntxiv. Cov khoom no ua rau nws nyiam cov khoom siv rau kev ua haujlwm siab rwb thaiv tsev, tshwj xeeb tshaj yog nyob rau hauv kev xav tau sectors xws li LNG cabrier kev tsim kho qhov twg thermal thiab mechanical kev ua tau zoo yog qhov tseem ceeb.

Nta & Cov txiaj ntsig

● Cov ntaub ntawv soluble heev

● Lub lev yog tsim los yooj yim delamination thiab repositioning.

● Ua kom yooj yim dua thiab ua raws li qhov kev txhawb nqa