High-Quality Woven Roving for Reinforcement Projects

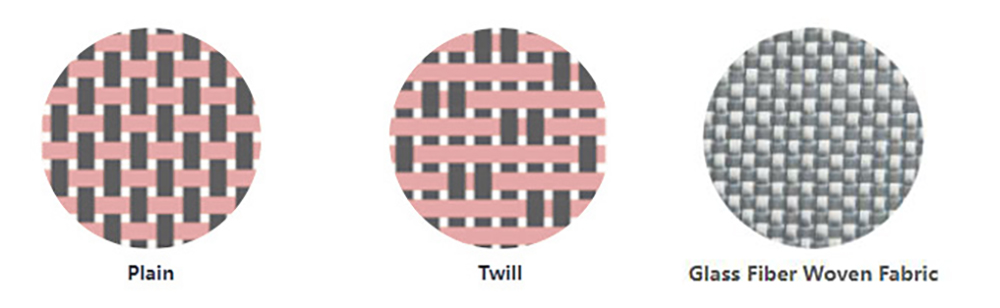

E-glass woven fabric consists of an orthogonal grid of interlaced warp and weft yarns (or rovings). Due to its high strength and durability, it is extensively used as a reinforcement material in a wide range of industries. Key applications include marine (e.g., boat hulls and decks), sports equipment, military and defense components, and automotive parts.

Features

● Excellent compatibility with UP/VE/EP

● Excellent mechanical property

● Excellent structural stability

● Excellent surface appearance

Specifications

|

Spec No. |

Construction |

Density (ends/cm) |

Mass (g/m2) |

Tensile Strength |

Tex |

|||||||||

|

Warp |

Weft |

Warp |

Weft |

Warp |

Weft |

|||||||||

|

EW60 |

Plain |

20 |

± |

2 |

20 |

± |

2 |

48 |

± |

4 |

≥260 |

≥260 |

12.5 |

12.5 |

|

EW80 |

Plain |

12 |

± |

1 |

12 |

± |

1 |

80 |

± |

8 |

≥300 |

≥300 |

33 |

33 |

|

EWT80 |

Twill |

12 |

± |

2 |

12 |

± |

2 |

80 |

± |

8 |

≥300 |

≥300 |

33 |

33 |

|

EW100 |

Plain |

16 |

± |

1 |

15 |

± |

1 |

110 |

± |

10 |

≥400 |

≥400 |

33 |

33 |

|

EWT100 |

Twill |

16 |

± |

1 |

15 |

± |

1 |

110 |

± |

10 |

≥400 |

≥400 |

33 |

33 |

|

EW130 |

Plain |

10 |

± |

1 |

10 |

± |

1 |

130 |

± |

10 |

≥600 |

≥600 |

66 |

66 |

|

EW160 |

Plain |

12 |

± |

1 |

12 |

± |

1 |

160 |

± |

12 |

≥700 |

≥650 |

66 |

66 |

|

EWT160 |

Twill |

12 |

± |

1 |

12 |

± |

1 |

160 |

± |

12 |

≥700 |

≥650 |

66 |

66 |

|

EW200 |

Plain |

8 |

± |

0.5 |

7 |

± |

0.5 |

198 |

± |

14 |

≥650 |

≥550 |

132 |

132 |

|

EW200 |

Plain |

16 |

± |

1 |

13 |

± |

1 |

200 |

± |

20 |

≥700 |

≥650 |

66 |

66 |

|

EWT200 |

Twill |

16 |

± |

1 |

13 |

± |

1 |

200 |

± |

20 |

≥900 |

≥700 |

66 |

66 |

|

EW300 |

Plain |

8 |

± |

0.5 |

7 |

± |

0.5 |

300 |

± |

24 |

≥1000 |

≥800 |

200 |

200 |

|

EWT300 |

Twill |

8 |

± |

0.5 |

7 |

± |

0.5 |

300 |

± |

24 |

≥1000 |

≥800 |

200 |

200 |

|

EW400 |

Plain |

8 |

± |

0.5 |

7 |

± |

0.5 |

400 |

± |

32 |

≥1200 |

≥1100 |

264 |

264 |

|

EWT400 |

Twill |

8 |

± |

0.5 |

7 |

± |

0.5 |

400 |

± |

32 |

≥1200 |

≥1100 |

264 |

264 |

|

EW400 |

Plain |

6 |

± |

0.5 |

6 |

± |

0.5 |

400 |

± |

32 |

≥1200 |

≥1100 |

330 |

330 |

|

EWT400 |

Twill |

6 |

± |

0.5 |

6 |

± |

0.5 |

400 |

± |

32 |

≥1200 |

≥1100 |

330 |

330 |

|

WR400 |

Plain |

3.4 |

± |

0.3 |

3.2 |

± |

0.3 |

400 |

± |

32 |

≥1200 |

≥1100 |

600 |

600 |

|

WR500 |

Plain |

2.2 |

± |

0.2 |

2 |

± |

0.2 |

500 |

± |

40 |

≥1600 |

≥1500 |

1200 |

1200 |

|

WR600 |

Plain |

2.5 |

± |

0.2 |

2.5 |

± |

0.2 |

600 |

± |

48 |

≥2000 |

≥1900 |

1200 |

1200 |

|

WR800 |

Plain |

1.8 |

± |

0.2 |

1.6 |

± |

0.2 |

800 |

± |

64 |

≥2300 |

≥2200 |

2400 |

2400 |

Packaging

● Fiberglass Stitched Mat rolls are available in diameters ranging from 28 cm to jumbo sizes.

● The product is available with paper cores of 76.2 mm (3") or 101.6 mm (4") inside diameter.

● Packaging: Each roll is individually wrapped in plastic and housed in a cardboard box.

● The rolls can be arranged on the pallets in either a vertical or horizontal position.

Storage

● Proper storage requires a cool and dry warehouse environment.

● For optimal storage, maintain a temperature range of 15°C to 35°C.

● For optimal storage conditions, the recommended relative humidity range is 35% to 75%.

● Prior to use, condition the mat at the worksite for at least 24 hours. This allows the material to reach equilibrium with the processing environment and ensures optimal performance.

● If a package is opened and partially used, it must be resealed immediately after each use to preserve the quality of the remaining material.