High-Quality Fiberglass Stitched Mats for Durable Performance

Stitched mat

Description

Stitched mat is produced by evenly distributing chopped fiberglass strands of specified length into a uniform web, which is then bound together using polyester stitching yarn. The strands are treated with a sizing system containing a silane coupling agent, ensuring compatibility with resins such as unsaturated polyester, vinyl ester, and epoxy. This uniform fiber distribution provides the mat with consistent and reliable mechanical properties.

Features

1. Consistent in both basis weight and thickness, with excellent structural integrity and no fiber shedding.

2.Rapid resin impregnation

3.Excellent interfacial adhesion

4.Excellent mold conformity

5.Readily separable

6.Visual appearance

7.Excellent mechanical performance

|

Product code |

Width(mm) |

Unit weight(g/㎡) |

Moisture Content(%) |

|

SM300/380/450 |

100-1270 |

300/380/450 |

≤0.2 |

Combo mat

Description

Fiberglass combination mats are engineered by integrating two or more distinct types of fiberglass materials through methods such as knitting, needling, or chemical bonding. This structure provides exceptional design flexibility, versatile formability, and broad adaptability across various applications.

Features & benefits

1. Fiberglass composite mats can be customized through the selection of various fiberglass materials and combination techniques, making them compatible with multiple manufacturing processes including pultrusion, RTM, and vacuum infusion. They also exhibit excellent conformability, enabling them to adapt effectively to complex mold geometries.

2. Can be tailored to precise strength specifications or cosmetic criteria.

3. Minimizes pre-forming trimming and fitting, while boosting production efficiency.

4. Optimizes material usage and reduces labor requirements, enhancing overall cost-effectiveness.

|

Products |

Description |

|

|

WR +CSM (Stitched or needled) |

Complexes are typically a combination of Woven Roving (WR) and chopped strands assembled by stitching or needling. |

|

|

CFM Complex |

CFM + Veil |

a complex product composed by a layer of Continuous Filaments and a layer of veil, stitched or bonded together |

|

CFM + knitted Fabric |

This complex is obtained by sewing a central layer of continuous filament mat with knitted fabrics on one or both sides CFM as the flow media |

|

|

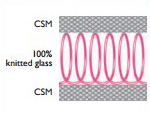

Sandwich Mat |

|

Designed for RTM closed mold applications. 100% glass 3-Dimensional complex combination of a knitted glass fiber core that is stitch bonded between two layers of binder free chopped glass. |