Fiberglass Mats: Durable Solutions for Various Applications

Stitched mat

Description

Stitched mat combines uniformly distributed, chopped fiberglass strands—stitched in place with polyester yarn—with a silane coupling agent treatment on the fibers. This ensures optimal compatibility with common resin systems like unsaturated polyester, vinyl ester, and epoxy. The result is a material with consistent fiber dispersion and reliable, high-performance mechanical properties.

Features

1. Uniform GSM and thickness, good integrity, without loose fiber

2.Fast wet-out

3. Good compatibility

4.Easily conforms to mold contours

5.Easy to split

6.Surface aesthetics

7.Good mechanical properties

|

Product code |

Width(mm) |

Unit weight(g/㎡) |

Moisture Content(%) |

|

SM300/380/450 |

100-1270 |

300/380/450 |

≤0.2 |

Combo mat

Description

Engineered by combining two or more fiberglass materials—whether by knitting, needling, or using binders—fiberglass combo mats offer superior design flexibility, material adaptability, and performance versatility to meet diverse application requirements.

Features & benefits

1. By allowing for variation in both the fiberglass materials and the combining process, these complex mats offer versatility to suit different production methods like pultrusion, RTM, and vacuum injection. They also provide good conformability, ensuring easy adaptation to intricate mold shapes.

2. It can be engineered to achieve the desired strength and aesthetic properties based on your requirements.

3. Reduces pre-processing and fitting work, boosting production efficiency.

4. Maximizes material and labor efficiency.

|

Products |

Description |

|

|

WR +CSM (Stitched or needled) |

Complexes are typically a combination of Woven Roving (WR) and chopped strands assembled by stitching or needling. |

|

|

CFM Complex |

CFM + Veil |

a complex product composed by a layer of Continuous Filaments and a layer of veil, stitched or bonded together |

|

CFM + knitted Fabric |

This complex is obtained by sewing a central layer of continuous filament mat with knitted fabrics on one or both sides CFM as the flow media |

|

|

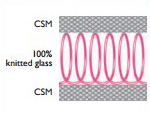

Sandwich Mat |

|

Designed for RTM closed mold applications. 100% glass 3-Dimensional complex combination of a knitted glass fiber core that is stitch bonded between two layers of binder free chopped glass. |