Fiberglass Continuous Filament Mat: Trusted by Industry Experts

Jiuding mainly offers four groups of CFM

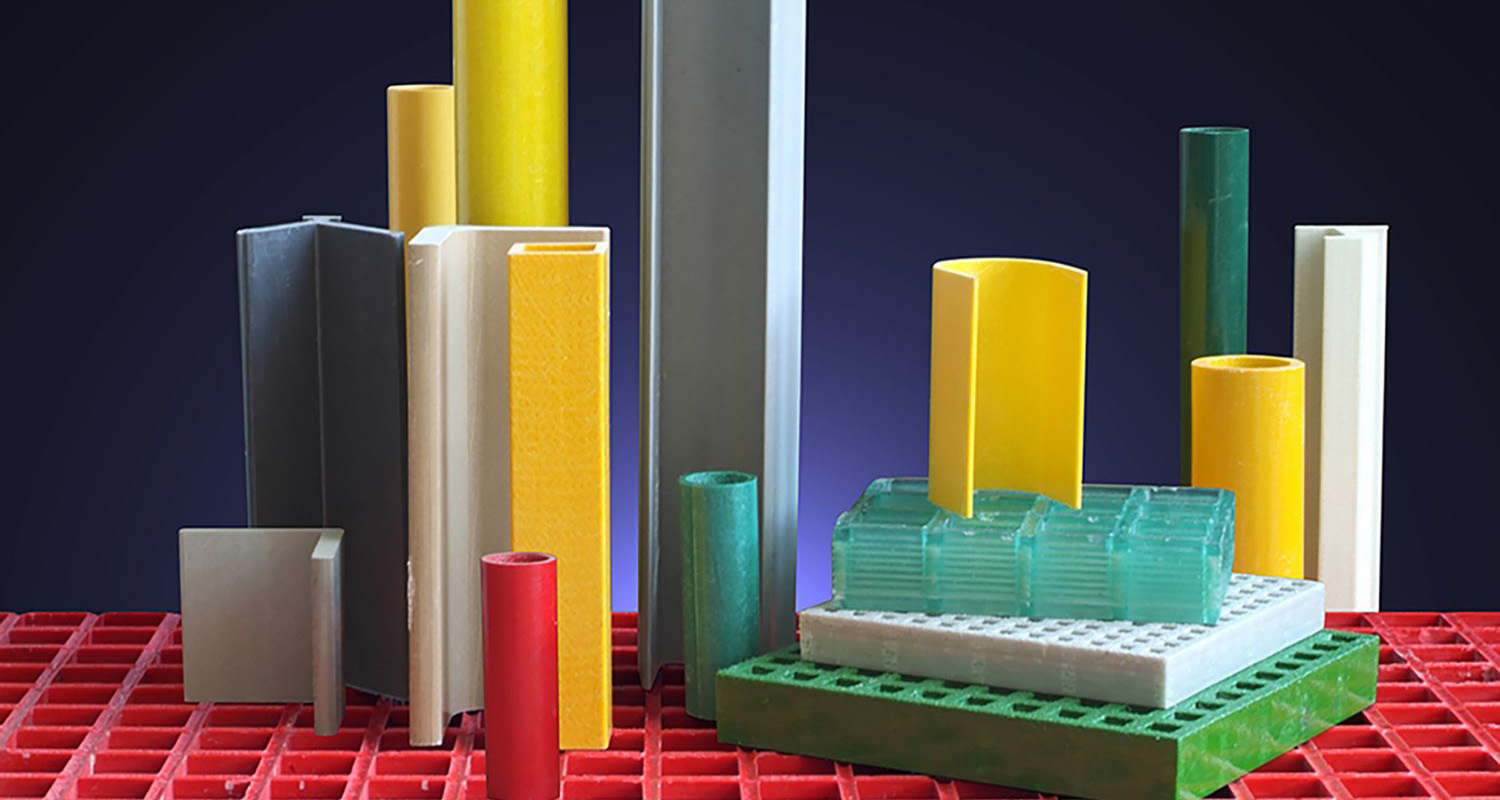

CFM for Pultrusion

Description

CFM955 is an ideal continuous filament mat for pultrusion profiling. Its key characteristics include rapid resin wet-through and excellent wet-out, ensuring high-quality production. The mat also offers exceptional conformability, superior surface smoothness on finished profiles, and high tensile strength.

Features & Benefits

● This mat retains high tensile strength even at elevated temperatures and after resin saturation. This property, combined with its compatibility with fast processing, enables it to meet demands for high throughput and productivity.

● Rapid resin penetration and thorough fiber saturation.

● Can be readily slit to custom widths.

● Pultruded profiles made with this mat exhibit superior strength in both transverse and random directions.

● Pultruded shapes exhibit excellent machinability, allowing them to be cut, drilled, and machined cleanly and efficiently.

CFM for Closed Molding

Description

CFM985 is compatible with a range of closed molding processes, including infusion, RTM, S-RIM, and compression molding. It is characterized by outstanding resin flow characteristics and serves a dual function: acting as a primary reinforcement material and/or an efficient flow medium between fabric layers.

Features & Benefits

● Exceptional resin permeability and distribution.

● High resistance to wash-out during resin injection.

● Conforms easily to complex shapes and contours.

●Enables effortless processing from roll to application, facilitating streamlined cutting and handling.

CFM for Preforming

Description

CFM828 is an excellent choice for preforming in closed mold applications, including high- and low-pressure RTM, infusion, and compression molding. Its integrated thermoplastic powder binder enables a high degree of deformability and improved stretchability during the preform process. This mat is commonly used in the production of structural and semi-structural parts for heavy-duty trucks, automotive assemblies, and industrial components.

CFM828 continuous filament mat offers a versatile range of customized preforming solutions tailored for closed molding technologies.

Features & Benefits

● Achieve a target/controlled resin content at the surface.

● Exceptional resin permeability

● Enhanced structural integrity

● Enables effortless processing from roll to application, facilitating streamlined cutting and handling.

CFM for PU Foaming

Description

CFM981 is ideally suited for polyurethane foaming process as the reinforcement of foam panels. The low binder content allows it to be dispersed evenly in PU matrix during foam expansion. It’s an ideal reinforcement material for LNG carrier insulation.

Features & Benefits

● Minimal binder content

● Mat layers exhibit limited interlayer integrity.

● Fine filament bundles