Fiberglass Continuous Filament Mat for Efficient Manufacturing Processes

Jiuding mainly offers four groups of CFM

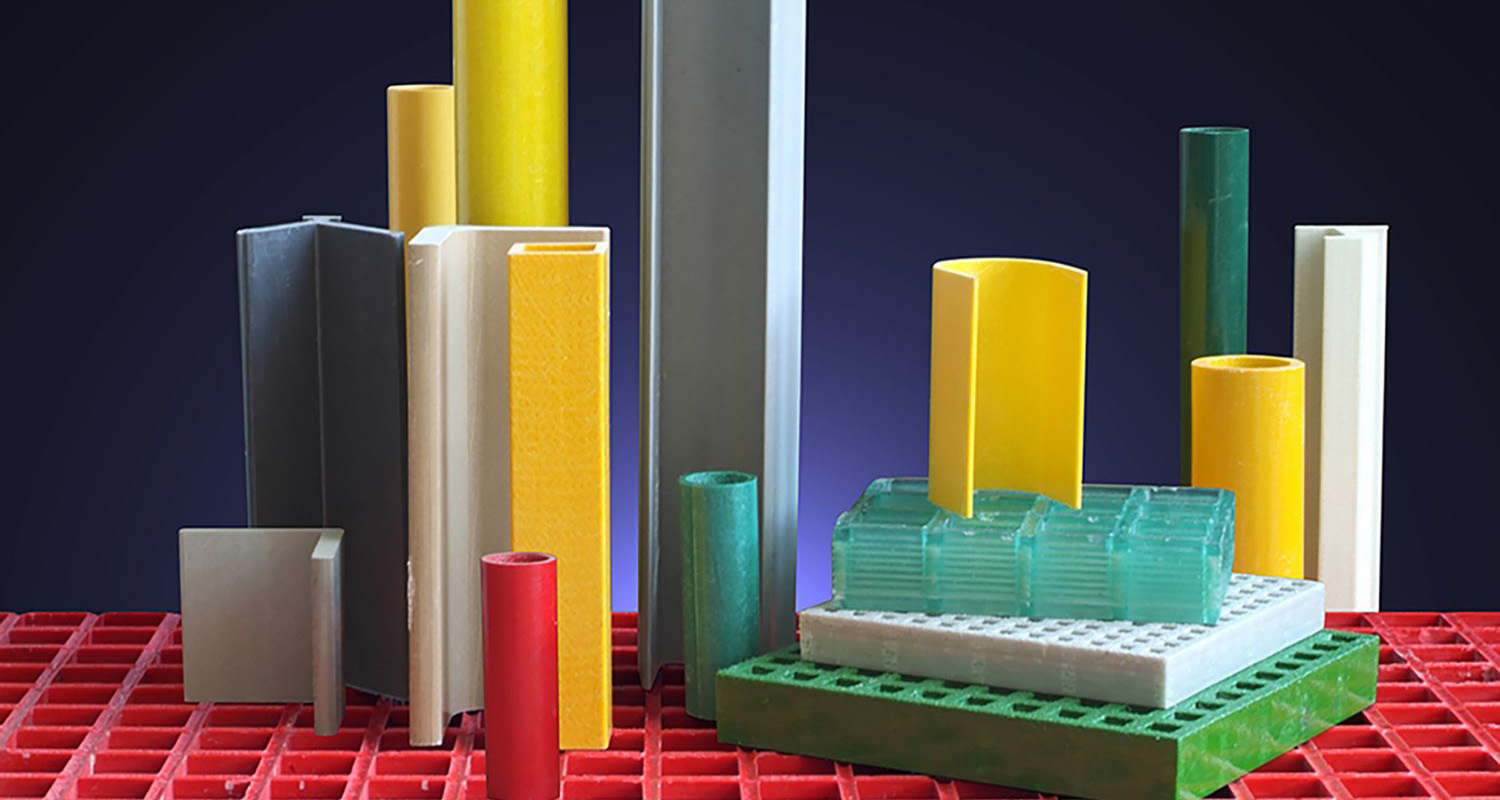

CFM for Pultrusion

Description

Engineered for pultrusion, CFM955 delivers critical advantages for profile manufacturing. It ensures fast processing thanks to quick resin wet-through and excellent wet-out, while simultaneously providing high mechanical strength, great conformability, and a very smooth surface finish.

Features & Benefits

● CFM955 excels in maintaining high tensile strength under demanding conditions—including elevated temperatures and resin wet-out. This reliability allows for exceptionally fast production speeds, supporting high throughput and maximizing your productivity.

● Exhibits quick resin penetration and ensures excellent fiber wet-out.

● Effortless processing that facilitates quick and clean splitting to required widths.

● Delivers exceptional multi-directional strength to pultruded shapes, enhancing structural integrity.

● Easy to machine, these pultruded profiles can be cleanly cut and drilled without splintering or cracking.

CFM for Closed Molding

Description

Ideally suited for infusion, RTM, S-RIM, and compression molding, CFM985 offers excellent flow properties. It functions effectively both as reinforcement and as a resin flow medium between fabric plies.

Features & Benefits

● Superior resin flow properties for rapid and uniform wet-out.

● Excellent stability under resin flow, minimizing displacement.

● Excellent drapability for seamless coverage over intricate molds.

● User-friendly material that is straightforward to unroll, cut to size, and handle on the shop floor.

CFM for Preforming

Description

CFM828 is exceptionally well-adapted for use in closed mold preforming applications—including high- and low-pressure RTM, infusion molding, and compression molding. Its integrated thermoplastic powder binder facilitates high deformability and improved stretchability during the preform shaping process. Typical applications span structural and semi-structural components in heavy truck, automotive, and industrial sectors.

As a continuous filament mat, CFM828 offers a versatile selection of customized preforming options tailored to diverse closed mold manufacturing requirements.

Features & Benefits

● Deliver a resin-rich surface layer for optimal finish quality.

● Superior resin saturation capability

● Superior mechanical properties

● Easy to unroll, cut, and handle.

CFM for PU Foaming

Description

CFM981 is an optimal reinforcement material for polyurethane foam panels, offering excellent compatibility with PU foaming processes. Its low binder content facilitates uniform dispersion within the polyurethane matrix during foam expansion, ensuring consistent reinforcement distribution. This mat is particularly well-suited for high-performance insulation applications, such as in LNG carriers, where reliable thermal and mechanical properties are essential.

Features & Benefits

● Low binder level

● The mat has a lofted, open structure with minimal layer bonding.

● Promotes better dispersion and uniformity in the composite