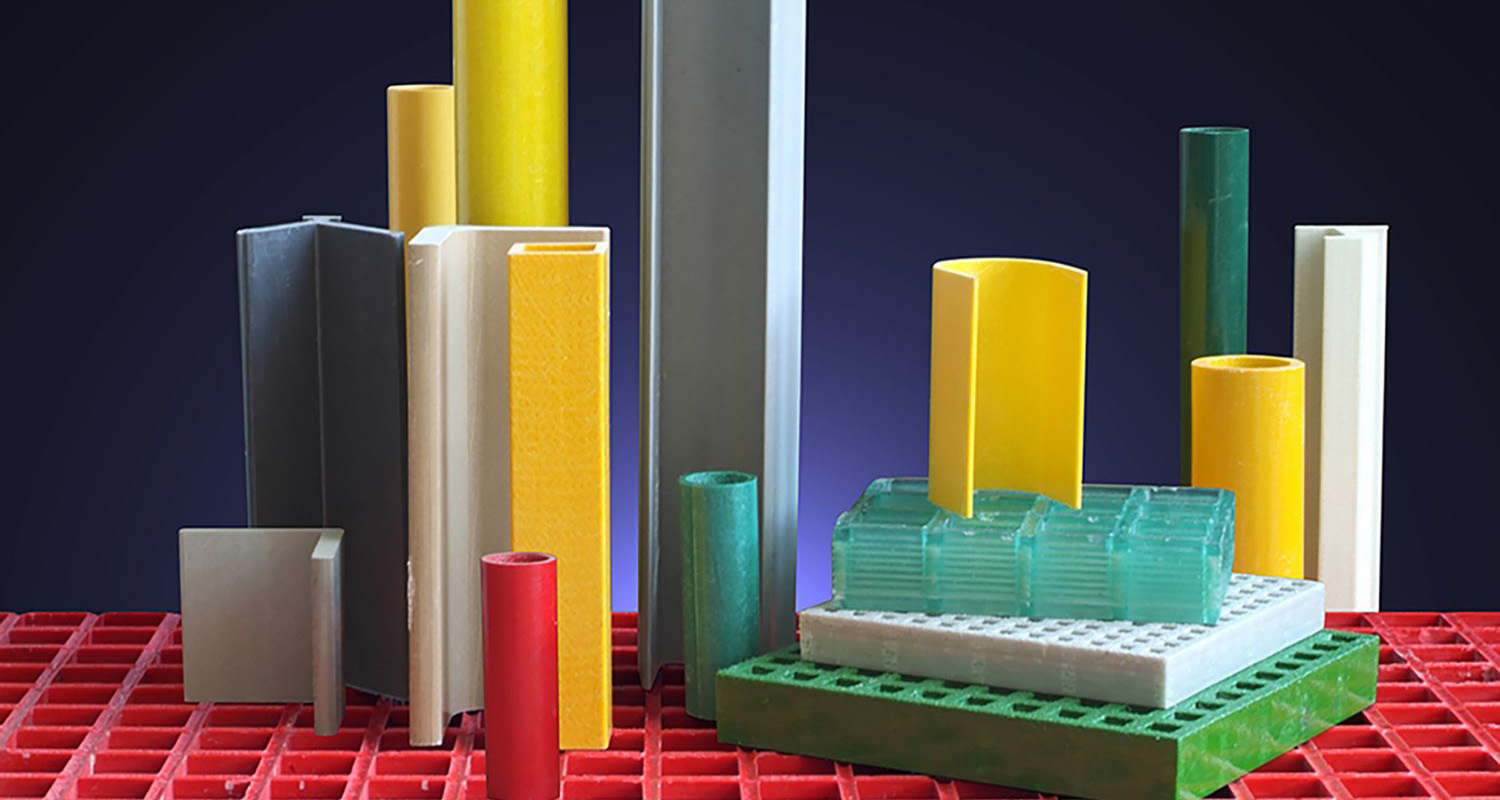

Fiberglass Continuous Filament Mat: Enhance Your Product’s Durability

Jiuding mainly offers four groups of CFM

CFM for Pultrusion

Description

CFM955 is a high-performance mat designed for pultrusion processes. It features rapid wet-through, excellent wet-out, high tensile strength, good conformability, and promotes a smooth surface finish on profiles.

Features & Benefits

● Offering high tensile strength even when resin-impregnated and at high temperatures, this mat is designed for fast production cycles and is capable of meeting high productivity requirements.

● Easy resin flow-through and complete fiber encapsulation.

● Designed for efficient slitting to various sizes, minimizing waste and downtime.

● Provides high strength in the transverse and random directions for pultruded profiles.

● Offers excellent machinability for ease of fabrication and post-processing.

CFM for Closed Molding

Description

CFM985 excels in infusion, RTM, S-RIM, and compression processes. Its key advantage lies in its superior flow characteristics, allowing it to be used not only for reinforcement but also as an effective flow path between layers of fabric reinforcement.

Features & Benefits

● Ensures complete resin saturation with minimal voids.

● Highly resistant to washing.

● Superior mold conformity.

● User-friendly material that is straightforward to unroll, cut to size, and handle on the shop floor.

CFM for Preforming

Description

CFM828 is specifically engineered for preform manufacturing in closed-mold processes including resin transfer molding (high and low pressure), vacuum infusion, and compression molding. The integrated thermoplastic powder binder enables exceptional deformability and improved stretch characteristics during preforming operations. This material is widely used in manufacturing structural components for heavy-duty trucks, automotive assemblies, and industrial equipment.

As a continuous filament mat, CFM828 provides comprehensive customized preforming options for various closed-mold production requirements.

Features & Benefits

● Maintain the recommended resin fraction at the mold surface.

● Optimal flow characteristics

● Achieves greater strength and durability

● Exhibits excellent lay-flat behavior and can be cut cleanly and handled with ease.

CFM for PU Foaming

Description

CFM981 is specifically engineered to serve as an optimal reinforcement material within polyurethane foam panels. Its characteristically low binder content promotes uniform dispersion throughout the expanding PU matrix, ensuring homogeneous reinforcement distribution. These properties make it a preferred material for high-performance insulation applications, particularly in demanding sectors such as LNG carrier construction where consistent thermal and mechanical performance is critical.

Features & Benefits

● Highly soluble binder

● The mat is designed for easy delamination and repositioning.

● Enables higher flexibility and conformability of the reinforcement