Fiberglass Cloth: Ideal for DIY and Professional Use

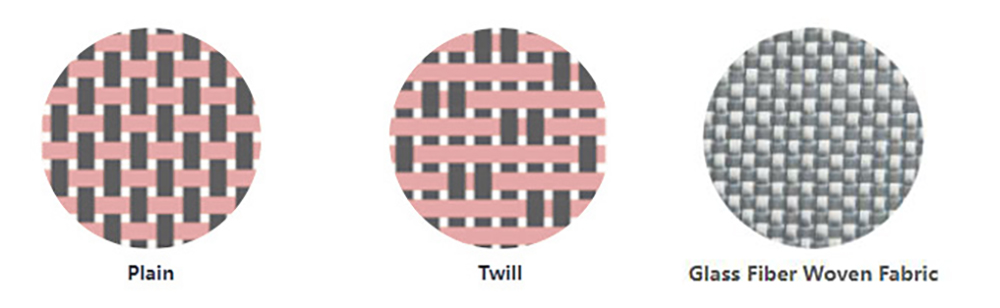

E-glass woven fabric is formed by the interlacing of horizontal and vertical yarns or rovings. It finds primary use across various fields such as boat hulls, sports equipment, military applications, and the automotive industry, among others.

Features

● Exhibits excellent compatibility with UP, VE, and EP.

● Superior mechanical properties

● Superior structural steadiness

● EExceptional surface appearance

Specifications

|

Spec No. |

Construction |

Density (ends/cm) |

Mass (g/m2) |

Tensile Strength |

Tex |

|||||||||

|

Warp |

Weft |

Warp |

Weft |

Warp |

Weft |

|||||||||

|

EW60 |

Plain |

20 |

± |

2 |

20 |

± |

2 |

48 |

± |

4 |

≥260 |

≥260 |

12.5 |

12.5 |

|

EW80 |

Plain |

12 |

± |

1 |

12 |

± |

1 |

80 |

± |

8 |

≥300 |

≥300 |

33 |

33 |

|

EWT80 |

Twill |

12 |

± |

2 |

12 |

± |

2 |

80 |

± |

8 |

≥300 |

≥300 |

33 |

33 |

|

EW100 |

Plain |

16 |

± |

1 |

15 |

± |

1 |

110 |

± |

10 |

≥400 |

≥400 |

33 |

33 |

|

EWT100 |

Twill |

16 |

± |

1 |

15 |

± |

1 |

110 |

± |

10 |

≥400 |

≥400 |

33 |

33 |

|

EW130 |

Plain |

10 |

± |

1 |

10 |

± |

1 |

130 |

± |

10 |

≥600 |

≥600 |

66 |

66 |

|

EW160 |

Plain |

12 |

± |

1 |

12 |

± |

1 |

160 |

± |

12 |

≥700 |

≥650 |

66 |

66 |

|

EWT160 |

Twill |

12 |

± |

1 |

12 |

± |

1 |

160 |

± |

12 |

≥700 |

≥650 |

66 |

66 |

|

EW200 |

Plain |

8 |

± |

0.5 |

7 |

± |

0.5 |

198 |

± |

14 |

≥650 |

≥550 |

132 |

132 |

|

EW200 |

Plain |

16 |

± |

1 |

13 |

± |

1 |

200 |

± |

20 |

≥700 |

≥650 |

66 |

66 |

|

EWT200 |

Twill |

16 |

± |

1 |

13 |

± |

1 |

200 |

± |

20 |

≥900 |

≥700 |

66 |

66 |

|

EW300 |

Plain |

8 |

± |

0.5 |

7 |

± |

0.5 |

300 |

± |

24 |

≥1000 |

≥800 |

200 |

200 |

|

EWT300 |

Twill |

8 |

± |

0.5 |

7 |

± |

0.5 |

300 |

± |

24 |

≥1000 |

≥800 |

200 |

200 |

|

EW400 |

Plain |

8 |

± |

0.5 |

7 |

± |

0.5 |

400 |

± |

32 |

≥1200 |

≥1100 |

264 |

264 |

|

EWT400 |

Twill |

8 |

± |

0.5 |

7 |

± |

0.5 |

400 |

± |

32 |

≥1200 |

≥1100 |

264 |

264 |

|

EW400 |

Plain |

6 |

± |

0.5 |

6 |

± |

0.5 |

400 |

± |

32 |

≥1200 |

≥1100 |

330 |

330 |

|

EWT400 |

Twill |

6 |

± |

0.5 |

6 |

± |

0.5 |

400 |

± |

32 |

≥1200 |

≥1100 |

330 |

330 |

|

WR400 |

Plain |

3.4 |

± |

0.3 |

3.2 |

± |

0.3 |

400 |

± |

32 |

≥1200 |

≥1100 |

600 |

600 |

|

WR500 |

Plain |

2.2 |

± |

0.2 |

2 |

± |

0.2 |

500 |

± |

40 |

≥1600 |

≥1500 |

1200 |

1200 |

|

WR600 |

Plain |

2.5 |

± |

0.2 |

2.5 |

± |

0.2 |

600 |

± |

48 |

≥2000 |

≥1900 |

1200 |

1200 |

|

WR800 |

Plain |

1.8 |

± |

0.2 |

1.6 |

± |

0.2 |

800 |

± |

64 |

≥2300 |

≥2200 |

2400 |

2400 |

Packaging

● The diameter of Fiberglass Stitched Mat roll could be from 28cm to jumbo roll.

● The roll is rolled with a paper core which has an inside diameter of 76.2mm(3 inch) or 101.6mm (4 inch ).

● Each roll is wrapped up in plastic bag or film and then packed in a cardboard box.

● The rolls are stacked vertically or horizontally on the pallets.

Storage

● Ambient condition: a cool & dry warehouse is recommended

● Optimal storage temperature: 15℃ ~ 35 ℃

● Optimal storage humidity: 35% ~ 75%.

● Before use, the mat should be acclimatized at the worksite for a minimum of 24 hours to ensure optimal performance.

● If some of the contents in a package unit have been used, the unit must be sealed before it is used again.