Durable Continuous Filament Mat for Polyurethane Foam

FEATURES & BENEFITS

● Extremely low binder level

● Weak interfacial bonding between the layers

● Low fiber areal weight

PRODUCT CHARACTERISTICS

| Product Code | Weight(g) | Max Width(cm) | Solubility in styrene | Bundle density(tex) | Solid content | Resin compatibility | Process |

| CFM981-450 | 450 | 260 | low | 20 | 1.1±0.5 | PU | PU foaming |

| CFM983-450 | 450 | 260 | low | 20 | 2.5±0.5 | PU | PU foaming |

● Other weights available upon request.

● Other widths available upon request.

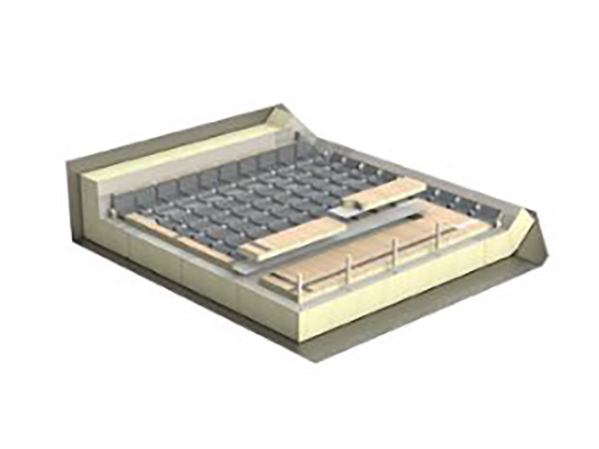

● The very low binder content of CFM981 ensures its even dispersion during polyurethane foam expansion, qualifying it as the ideal reinforcement for LNG carrier insulation systems.

PACKAGING

● Choose from 3" (76.2 mm) or 4" (102 mm) inner core diameters, each with a minimum 3 mm wall thickness. This construction guarantees robust strength and reliable stability.

● To ensure product integrity, every unit (roll and pallet) is individually wrapped in a protective film. This packaging offers comprehensive protection from environmental and handling hazards throughout the supply chain.

● Upon dispatch, each unit (roll and pallet) is assigned a unique barcode. This code contains comprehensive production details such as weight, number of rolls, and manufacture date, enabling full traceability and streamlined inventory control.

STORAGING

● CFM must be stored under cool, dry warehouse conditions to prevent degradation and ensure consistent performance.

● Store at 15°C to 35°C to preserve material properties.

● Store at 35-75% RH to maintain optimal handling and application properties.

● Stack pallets a maximum of two layers high to prevent deformation.

● Condition the mat in the worksite environment for at least 24 hours before application for optimal performance.

● Any packaging unit that has been opened should be promptly and securely resealed to maintain its specified properties and protect the remaining contents from contamination or moisture.