Cost-Effective Fiberglass Continuous Filament Mat for Your Needs

Jiuding mainly offers four groups of CFM

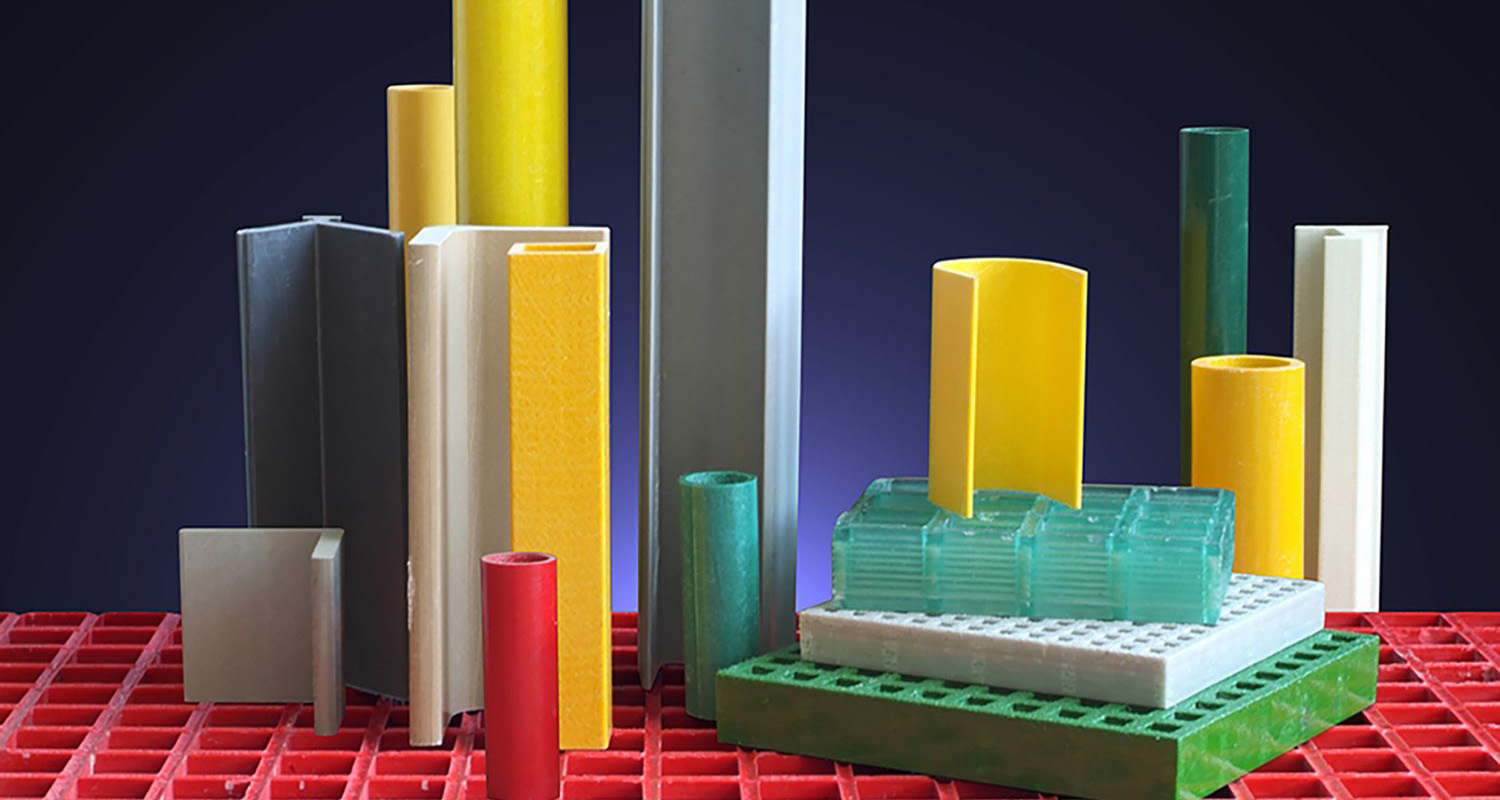

CFM for Pultrusion

Description

CFM955 Pultrusion Mat Optimized for profile production with: rapid resin penetration, uniform wet-out, excellent mold conformity, smooth finish, high strength.

Features & Benefits

● High-strength mat maintains tensile integrity under heat and resin saturation, enabling high-speed production and efficient throughput.

● Fast wet-through, good wet-out

● Easy processing (easy to split into various width)

● Outstanding transverse and random direction strengths of pultruded shapes

● Good machinability of pultruded shapes

CFM for Closed Molding

Description

CFM985 excels in infusion, RTM, S-RIM, and compression molding, offering dual reinforcement and resin flow enhancement between fabric layers.

Features & Benefits

● Superior Resin Permeability – Ensures rapid, uniform saturation

● Exceptional Wash Durability – Maintains integrity during processing

●Excellent Mold Adaptability – Conforms seamlessly to complex shapes

● User-Friendly Workability – Simplifies unrolling, cutting, and placement

CFM for Preforming

Description

CFM828 is perfect for closed-mold processes like RTM, infusion, and compression molding. Its special thermoplastic binder allows easy shaping and stretching during preforming. Widely used in trucks, cars, and industrial parts, it offers customized solutions for various needs.

Features & Benefits

● Precise resin surface saturation - Ensures perfect resin distribution and bonding

● Exceptional flow properties - Enables fast, uniform resin penetration

● Enhanced mechanical integrity - Delivers superior structural strength

● Excellent workability - Facilitates effortless unrolling, cutting and installation

CFM for PU Foaming

Description

CFM981 is optimized for PU foam reinforcement, featuring low binder content for uniform dispersion. Ideal for LNG insulation panels.

Features & Benefits

●Minimal binder content

● Reduced interlayer cohesion

● Ultra-light fiber bundles