Continuous Filament Mat for PU Foam Applications

FEATURES & BENEFITS

● Minimal binder content

● Poor structural integrity between the mat layers

● Low tow linear density

PRODUCT CHARACTERISTICS

| Product Code | Weight(g) | Max Width(cm) | Solubility in styrene | Bundle density(tex) | Solid content | Resin compatibility | Process |

| CFM981-450 | 450 | 260 | low | 20 | 1.1±0.5 | PU | PU foaming |

| CFM983-450 | 450 | 260 | low | 20 | 2.5±0.5 | PU | PU foaming |

● Other weights available upon request.

● Other widths available upon request.

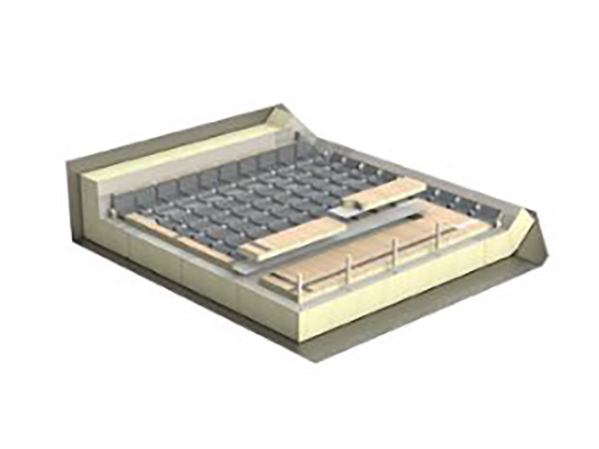

● CFM981, with its very low binder content, disperses evenly during PU foam expansion, making it an ideal reinforcement material for LNG carrier insulation.

PACKAGING

●The inner core is offered in two standard diameters: 3" (76.2 mm) or 4" (102 mm). Both options feature a minimum wall thickness of 3 mm to maintain structural strength and stability.

● Each roll and pallet is packaged in protective film, providing defense against dust, moisture, and physical damage during transit and storage.

● Each roll and pallet is fitted with a traceable barcode containing essential data—including weight, roll count, and manufacturing date—to facilitate efficient tracking and inventory management.

STORAGING

● It is recommended to store CFM in a cool, dry warehouse environment to preserve its material integrity and performance properties.

● The optimal storage temperature should be maintained between 15°C and 35°C to prevent material degradation.

● The relative humidity (RH) in storage should be controlled within 35% to 75% to prevent issues caused by excessive moisture absorption or excessive dryness.

● Pallets should be stacked no more than two high to avoid deformation or compression damage.

● It is essential to condition the mat in the worksite environment for a minimum of 24 hours prior to use to ensure optimal processing performance.

● Reseal any partially used package immediately after use to preserve product quality and prevent contamination or moisture absorption.