Combo Mats: Your Go-To for Versatile Solutions

Stitched mat

Description

Stitched mat is manufactured by uniformly spreading the chopped strands based on a certain length into flake and then stitched with polyester yarns. Fiberglass strands are equipped with sizing system of silane coupling agent, which is compatible with unsaturated polyester, vinyl ester, epoxy resin systems, etc. Evenly distributed strands ensure its stable and good mechanical properties.

Features

1. Consistent grams per square meter (GSM) and thickness, strong integrity, and no loose fibers.

2.Fast wet-out

3. Excellent compatibility

4. Easily adapts to the shape of the mold

5. Quick to split apart

6.Visual appeal of the surface

7.Superior mechanical characteristics

|

Product code |

Width(mm) |

Unit weight(g/㎡) |

Moisture Content(%) |

|

SM300/380/450 |

100-1270 |

300/380/450 |

≤0.2 |

Combo mat

Description

Fiberglass combo mats are a combination of two or more type fiberglass materials through knitting, needling or bound by binders, with outstanding designability, flexibility, and a wide range of adaptability.

Features & benefits

1. By choosing different fiberglass material and different combination process, Fiberglass complex mats can suit different process such as pultrusion, RTM, vacuum inject, etc. Good conformability, can adapt to complex molds.

2. Can be customized to meet specific strength or appearance requirements.

3. Reduced pre-mold dressing and tailoring, increased productivity

4. Efficient use of material and labor cost

|

Products |

Description |

|

|

WR +CSM (Stitched or needled) |

Complexes are typically a combination of Woven Roving (WR) and chopped strands assembled by stitching or needling. |

|

|

CFM Complex |

CFM + Veil |

a complex product composed by a layer of Continuous Filaments and a layer of veil, stitched or bonded together |

|

CFM + knitted Fabric |

This complex is obtained by sewing a central layer of continuous filament mat with knitted fabrics on one or both sides CFM as the flow media |

|

|

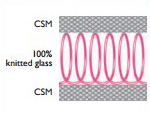

Sandwich Mat |

|

Designed for RTM closed mold applications. 100% glass 3-Dimensional complex combination of a knitted glass fiber core that is stitch bonded between two layers of binder free chopped glass. |