Combo Mats: The Perfect Solution for Various Tasks

Stitched mat

Description

Stitched mat is produced through a process where fiberglass strands, precisely cut to defined lengths, are evenly distributed into a layered flake structure and mechanically secured with interlaced polyester threads. The fiberglass materials are treated with a silane-based sizing system, enhancing their adhesion compatibility with various resin matrices including unsaturated polyester, vinyl ester, and epoxy. This uniform arrangement of reinforcement fibers guarantees consistent load-bearing capacity and structural integrity, resulting in reliable mechanical performance across composite applications.

Features

1. Precise GSM and thickness control, superior mat integrity, and minimal fiber separation

2.Fast wet-out

3.Excellent resin compatibility

4.Easily conforms to mold contours

5.Easy to split

6.Surface aesthetics

7.Reliable structural performance

|

Product code |

Width(mm) |

Unit weight(g/㎡) |

Moisture Content(%) |

|

SM300/380/450 |

100-1270 |

300/380/450 |

≤0.2 |

Combo mat

Description

Fiberglass composite mats are engineered by integrating multiple reinforcement types through mechanical bonding (knitting/needling) or chemical binders, offering exceptional design flexibility, formability and broad application versatility.

Features & benefits

1. By choosing different fiberglass material and different combination process, Fiberglass complex mats can suit different process such as pultrusion, RTM, vacuum inject, etc. Good conformability, can adapt to complex molds.

2. Tailorable to achieve targeted mechanical performance and aesthetic specifications.

3. Minimizes pre-forming preparation while enhancing production efficiency

4. Efficient use of material and labor cost

|

Products |

Description |

|

|

WR +CSM (Stitched or needled) |

Complexes are typically a combination of Woven Roving (WR) and chopped strands assembled by stitching or needling. |

|

|

CFM Complex |

CFM + Veil |

a complex product composed by a layer of Continuous Filaments and a layer of veil, stitched or bonded together |

|

CFM + knitted Fabric |

This composite structure is manufactured by stitch-bonding a continuous filament mat (CFM) core with knitted fabric reinforcement on single or dual surfaces, utilizing the CFM as the primary resin flow medium |

|

|

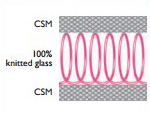

Sandwich Mat |

|

Designed for RTM closed mold applications. 100% glass 3-Dimensional complex combination of a knitted glass fiber core that is stitch bonded between two layers of binder free chopped glass. |